Expanding Environment-conscious Products and Services

The Kubota Group is contributing to protecting the global environment and solving social issues in the food, water and living environment fields through the provision of environment-conscious products and services. The Group conducts environmental assessment of products in the design and development stages, and promotes environment- friendliness over the entire product lifecycle, from the procurement of raw materials to the disposal of products. The Group internally certifies exceptionally environment-conscious products as Eco-Products, and is working to expand its lineup of certified products.

- Activities towards achieving SDGs

- Environmental Considerations in the Product Life Cycle

- Internal Certification System for Eco-Products

- The Evolution of Environment-conscious Products and Services

- Managing Used Products

Activities towards achieving SDGs

| Related SDGs and target |

|

|---|---|

| Major Activity Content |

|

| 2030/2025 Activity Targets (KPIs) |

|

Environmental Considerations in the Product Life Cycle

1. Major Initiatives to Ensure Environment-friendliness

2. Analysis of Greenhouse Gas Emissions in the Product Lifecycle

The Kubota Group handles a diverse range of products, from agricultural and construction machinery to pipe systems and water treatment equipment. As part of its product environmental assessment, the Group conducts lifecycle assessment (LCA) for its major products to determine the amount of greenhouse gas emissions over each product lifecycle. The results of the LCA were subject to third-party review in 2014 by the Japan Environmental Management Association for Industry.

-

Results of LCA: Proportions of Greenhouse Gases

- *1.LCA results for tractors were calculated based on the assumption of towing and transporting work for 5,000 hours by the M9540DTHQ-EC agricultural tractor in France.

- *2.LCA results for ductile iron pipes were calculated based on the data reported in the “Study on Piping Technologies for Sustainable Water Supply Service” (Japan Water Research Center). The proportions of raw material procurement, manufacturing, and product transportation were determined according to Kubota's CO2 emissions data.

Greenhouse gases emitted in the use stage account for around 90% in the lifecycle of agricultural tractors, while gases emitted in the manufacturing and construction stage account for around 90% in ductile iron pipes. Thus, the frequency and scale of environmental loads in the lifecycle vary depending on the product type. The Kubota Group enhances its environment-conscious products and services by reflecting the results of the analysis of environmental loads in the product lifecycle in its environment-conscious design development.

3. Major Initiatives to Ensure Environment-friendliness by Product Group

4. Examples of Initiatives to Ensure Environment-friendliness

-

①Mini Cultivator

-

②Zero-Turn Mowers

-

③Air-conditioning equipment

-

④Combine Harvesters

-

⑤Plastic Pipes

-

⑥Johkasou

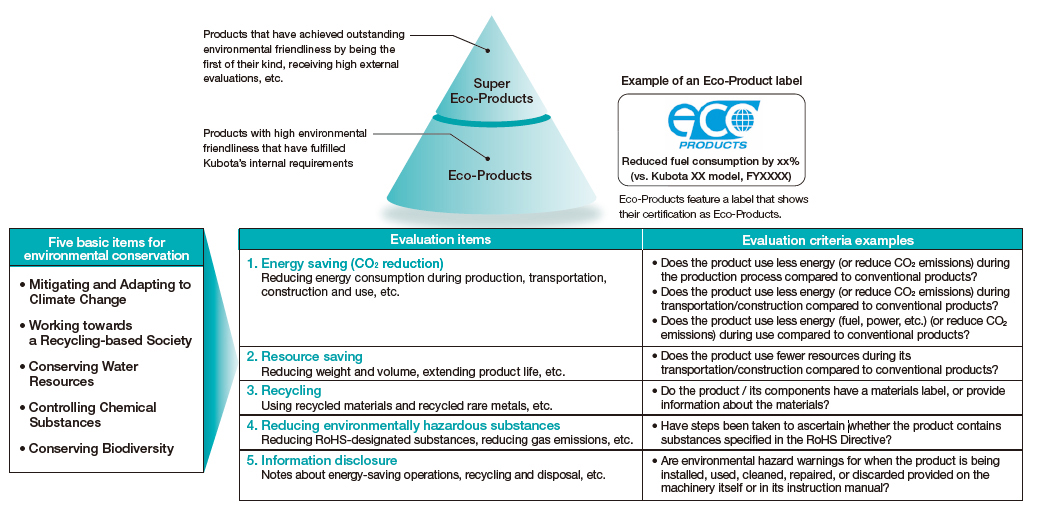

Internal Certification System for Eco-Products

1. Regarding the Internal Certification System for Eco-Products

The Kubota Group's internal certification system for Eco-Products was introduced to internally certify products with exceptional environmental friendliness. We evaluate products in accordance with matters related to the five basic items for environmental conservation in the Kubota Group's environmental management, namely, “Tackling Climate Change,” “Working towards a Recycling-based Society,” “Conserving Water Resources,” “Controlling Chemical Substances,” and “Conserving Biodiversity,” and certify those products that satisfy our internal standards as Eco-Products.

2. Eco-Products Certification Committee

The Eco-Products Certification Committee, chaired by the General Manager of the Manufacturing Headquarters, consists of the committee members elected from each Division, as well as the Research and Development Management Department and the Environmental Protection Department. Upon receiving an application from each Division for the certification of a product, the Committee examines the product's adequacy as an Eco-Product and gives certification.

3. The Pathway to Expanding Certified Eco-Products

Based on our internal certification system established for Eco-Products, the Kubota Group certified an additional 37 products in FY2023, bringing the total number of certified Eco-Products to 440. The sales ratio of Eco-Products was 70.1% versus the Medium-Term Environmental Conservation Targets 2025 of 70% or higher. Also in FY2023, two of our electric tractors—both of which have earned favorable reviews in the market—were newly certified as Super Eco-Products. Going forward, we will expand our Eco-Products lineup by continuing to promote the development of environment-conscious products demanded by our customers and society, including products that are energy- saving, lightweight, miniaturized, long-lived, easy maintenance, and compliant with environmental regulations.

-

Trends in Numbers of Eco-Product Certifications (Total)

-

Trends in Sales Ratio of Eco-Products*

- *1. The sales ratio of products that have fulfilled the internal requirements in our own Eco-Products Certification System Sales ratio of Eco-Products (%) = Sales of Eco-Products / Sales of products (excluding construction work, services, software, parts and accessories) × 100

- *2. From FY2023, sales of TXAX, the ceramic material have been excluded from the calculations because TXAX is considered to be a part. If TXAX was included, the FY2023 sales ratio of eco-products would come to 69.9%.

4. List of Products Certified as Eco-Products

The Evolution of Environment-conscious Products and Services

-

①The Evolution of Iron Pipes

-

②The Evolution of Engines

-

③The Evolution of Scales

-

④The Evolution of Kubota Tractors

-

⑤Evolution and History of Rice Transplanters

Managing Used Products

-

DPF muffler

Provision of recycled products under the DPF Eco Program

The Kubota Group has several services in which used products and parts are collected for recycling. Kubota Engine Japan Corporation manages the DPF Eco Program to encourage the recycling of diesel particulate filters (DPF). A DPF is a filtering device that removes particulate matter from the exhaust gas of diesel engines. It does this by collecting and regularly burning off the harmful fine particles contained in the gas emitted by the engine. However, ash that cannot be completely removed through combustion continues to accumulate in the DPF. Under this program, recycled DPFs with the same level of performance as a brand new device are provided to customers after being cleaned and inspected in accordance with Kubota's specifications. Kubota Engine Japan also operates a remanufactured parts program for mainly starting motors and alternators used in Kubota engines. These parts are disassembled, cleaned, and given new components so they can be used again like a new product. Kubota Engine America Corporation also provides a similar remanufactured parts service.

Siam Kubota Corporation Co., Ltd. in Thailand manufactures and sells tractors, combine harvesters, cultivators, diesel engines, and other machinery. In addition to this, it repairs and refurbishes machinery traded in by customers when they purchase a new product and provides assistance to the dealers that sell them as authorized second-hand equipment.

In the water and environment field, Kubota provides submerged membrane units for purifying household and industrial wastewater. To ensure the smooth operation of water treatment facilities, it is essential that the submerged membranes are maintained, including the regular replacement of membrane cartridges. Kubota Membrane Co., Ltd. not only examines and replaces the membrane cartridges, but it also recycles them in an effort to contribute to the reduction of waste emissions.

Kubota ChemiX Co., Ltd., a Group company involved in the manufacture and sale of plastic pipes and fittings, is also engaged in the effective use of resources by making and selling rigid three-layer PVC pipes with the use of recycled PVC that has been processed from cleaned and pulverized waste material. Moreover, KUBOTA Environmental Engineering Corporation—which undertakes construction, maintenance, and operational management of water and environmental facilities—provides engineering services to facilities that pulverize and sort plastic waste for use as fuel and material.

These initiatives mean the Kubota Group can avoid using new raw materials, which in turn helps lower the amount of energy used to make new products and reduces greenhouse gas emissions. We will continue to promote measures that contribute to the effective utilization of resources whilst also meeting the needs of our customers.

Recycled Products

The ductile iron pipes, fittings, and machine cast products (such as engine crankcases, cylinder heads, and transmission cases) manufactured by the Kubota Group are produced mainly from scrap iron collected from external sources and within our plants. Iron can be turned into new products without significant quality degradation during the recycling process because impurities are largely removed. As one of the Medium-Term Environmental Conservation Targets 2025, we aim to maintain the usage ratio of recycled material of at least 70% in order to promote the use of recycled materials.

-

Ductile iron pipe manufactured from mostly scrap iron

-

Usage Ratio of Recycled Materials (%)*1, 2

- *1.Usage ratio of recycled materials in cast metal products and parts manufactured by the Kubota Group, such as ductile iron pipes, fittings, and machine cast products (engine crankcases, etc.).

- *2.From FY2023, the calculation method has been changed to exclude old pig iron generated within the same business site from the calculations. This has been applied retroactively.