Greenhouse Horticulture

Autonomous Control Aims to Make Greenhouse Horticulture Labor-saving and Efficient for Everyone

The Issues Facing Greenhouse Horticulture and Smart Solutions

Given the instability of open-field cultivation due to worsening of climate change, as well as the global population increase and concentration of populations in urban areas, greenhouse horticulture is gaining attention. There are hopes that this method can be used to dependably produce high value-added crops without being affected by weather, local climate, or location.

However, due to its nature, greenhouse horticulture requires careful environmental control within facilities and frequent management tasks, which demand significant labor. Additionally, it faces the same challenges as agriculture as a whole, such as aging workforces and labor shortages. As a result, there is a growing need for production methods that reduce reliance on experience, intuition, and subjective judgment. Furthermore, since greenhouse horticulture requires substantial resources and energy, minimizing their environmental impact is also a key concern.

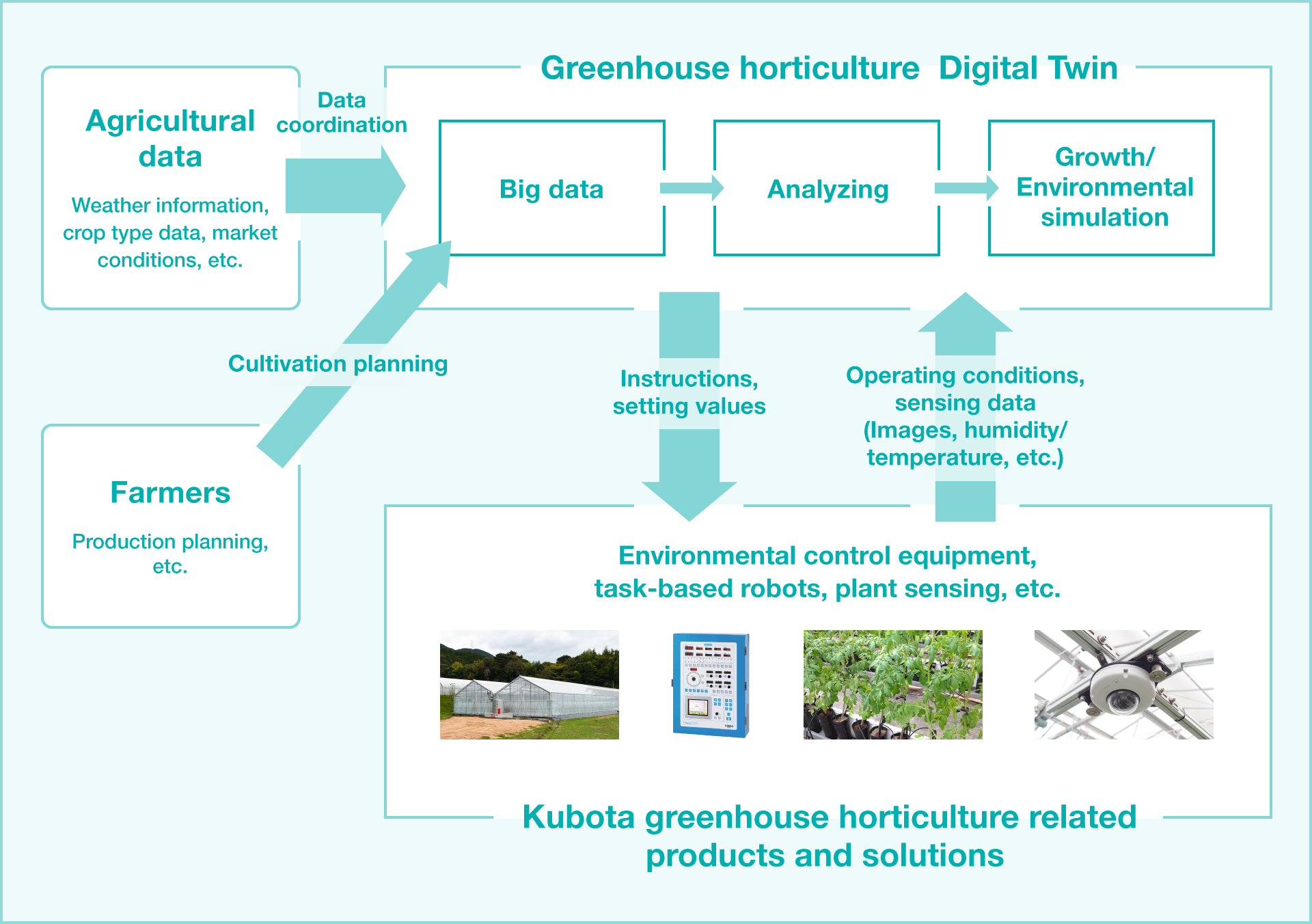

To address these issues, Kubota is working toward autonomous capabilities for greenhouse horticulture that enable all users to save labor and improve efficiency by utilizing plant phenotyping technologies, growth monitoring, and diagnostic and predictive technologies.

-

Some examples of solutions for greenhouse horticulture.

Visualizing Crop Growth with Sensing Technologies

Traditionally, greenhouse horticulture has relied on visual observations for management decisions, with the experience and skills of experts playing the key role in determining the success of production. That is why Kubota is working to develop a data-driven system to make cultivation accessible even to those with little experience.

Specifically, this system uses image sensing technology to digitize crop growth information in real time, including aspects like leaf wilting. This will enable even inexperienced farmers to assess plant stress levels more easily. Additionally, its automatic watering system activates when wilting reaches a certain threshold, reducing labor in cultivation management while ensuring stable quality and yield.

Utilizing Data to Maximize Productivity

Furthermore, crop data derived through image sensing technology, along with environmental and weather data from facilities, is used to predict harvest timing and yield. Based on these predictions, the system can recommend management tasks needed to optimize environmental conditions and cultivation plans, supporting farmers in their decision-making. This enables data-driven greenhouse horticulture that ensures stable and maximized production without relying on experience or intuition.

Additionally, data-driven environmental control helps minimize resource input, reducing environmental impact.

Kubota’s Vision for Labor-saving, Efficient, and Eco-friendly Greenhouse Horticulture

Kubota aims for autonomous cultivation through greenhouse horticulture that allows anyone to achieve significant labor savings and efficiency through analysis of crop sensing data, environmental conditions in the greenhouse, and cultivation tasks, along with integration of this data with environmental control systems and equipment. And by combining data-driven cultivation with resource-efficient technologies, farmers can maximize yields and quality while using minimal resources, minimizing the environmental impact of greenhouse horticulture.