KUBOTA TECHNICAL REPORT No.56 JANUARY 2024

In Japan, we opened a new R&D base, the Global Institute of Technology, in 2022. We will build a truly global R&D system with six regions around the world, adding China and India to the existing bases of Thailand, North America, Europe, and Japan. We will work to build a system where locally oriented R&D bases are organically bound so that we can quickly solve social issues in each region. The KUBOTA TECHNICAL REPORT No. 56 introduces some examples of global R&D, such as IoT drones that contribute to improving the efficiency of agricultural work in Thailand, optimal fertilizer application using TIM (Tractor Implement Management) in Europe, and R&D bases in North America. We hope you will take the time to read it.

Farm & Industrial Machinery

Development of Compact Electric Tractor LXe-261 for the European MarketTractor Engineering Dept. Ⅰ

In response to growing environmental concerns and the pursuit of carbon neutrality, European regulatory bodies are tightening restrictions on internal combustion engine emissions, which necessitates the development of compliant products that adhere to these regulations. In line with the European market's commitment to carbon neutrality, Kubota has developed the Compact Electric Tractor "LXe-261" as its first electric tractor. This paper focuses on the engineering challenges encountered during the development of this groundbreaking electric tractor, including issues related to ensuring framestrength and handling high-voltage harnesses.

- Electric Tractor

- Electrified Devices

- Strength Analysis

- 【Related SDGs】

-

Development of REXIA Series Tractor for Domestic Market with “Go-Straight Function”Tractor Engineering Dept. Ⅱ / Farm and Industrial Machinery R&D Dept. ⅠFarm and Industrial Machinery R&D Dept. Ⅳ / Farm and industrial Machinery R&D Dept. Ⅵ

The Japanese agricultural sector is undergoing a significant transformation, characterized by an aging workforce, farm consolidation, and increasing farm sizes. These larger-scale farms face the challenge of managing their operations efficiently and sustainably.To address these challenges, Kubota is actively developing smart agriculture technologies that attempt to enhance production efficiency, reduce labor requirements, and alleviate the physical demands of farm work. Kubota has already launched a selfoperating tractor, however, now it has developed the “Rexia-GS” tractor that features a go-straight function for entry-level model. This innovative feature demonstrates Kubota's commitment to providing farmers with practical and effective smart agriculture solutions.

- Smart Agriculture

- AutoSteer Systems

- GNSS

- Electronic Control

- 【Related SDGs】

-

Development of Electric Zero-Turn Mower Ze series for the European MarketTractor Engineering Dept. ⅢFarm and Industrial Machinery R&D Dept. Ⅱ

In 2024, Kubota will introduce the electric Zero Turn Mower Ze series (Ze-481/Ze-421) for the European market. The Ze series is Kubota's first lithium-ion battery-powered riding lawn mower developed for professional markets such as municipalities and contractors operating within the Europe. It features a replaceable battery pack mechanism, multiple motors, and inverters for driving and mowing to enable the oneday work required by professionals. We will introduce novel developed mechanical structures and vehicle control technology, battery packs, and an electrification system development technology that contribute to the conservation of the global environment and achieve these goals.

- Electrification

- Lithium-Ion Batteries

- Motors/Inverters

- Coordinated Control

- 【Related SDGs】

-

Development of Seven-Rows Head-feeding Combine Harvester DR7130Combine Harvester Engineering Dept.

In Japan, fallow land, which is increasing due to the aging of farmers and shortage of successors, is being consolidated to large-scale farmers. Consequently, the amount of crop fields per household to farmers is increasing, which necessitates the improvement of work efficiency. In addition, to improve management efficiency, the planting of new demand rice such as feed rice is increasing; however, these varieties have limitations such as long culms that are difficult to reap. To address these limitations, Kubota has developed a novel seven-rows combine harvester “DR7130” that combines “optimal handling” and “crop transport performance.” This paper introduces the development technologies that facilitate this novel concept.

- Combine Harvester

- High Working Capacity

- Good Handling

- High Performance

- 【Related SDGs】

-

Development of Autonomous Driving Rice Transplanter NW8SATransplanter Engineering Dept. / Farm and Industrial Machinery R&D Dept. ⅢFarm and Industrial Machinery R&D Dept. Ⅵ / Farm and Industrial Machinery R&D Dept. Ⅰ

Kubota introduced a rice transplanter with a straight-line motion function (hereinafter called “Go Straight (GS)” function). However, it is difficult for unskilled workers to achieve rice planting on entire rice fields via the GS function alone. Therefore, to realize the objective behind this development concept, which was to enable even unskilled/inexperienced rice-farm workers to easily and stress-freely plant entire rice fields, we developed a rice transplanter with an automated driving function. In this paper, we described the working route for automated driving, trace running control at the outer areas of rice fields, and characteristic technologies unique to autonomous driving.

- Rice Tansplanter

- Autonomous Driving

- Working Route

- Trace Running

- 【Related SDGs】

-

Development of the Electrically Controlled Small Diesel Engine D902-KEngine Engineering Dept. Ⅰ

The NSM series engine, which has high power density and high environmental performance by improving its unique combustion system, E-TVCS, to achieve both high power density and high environmental performance, contributes to the increased competitiveness of this machine. In recent years, in addition to strictly exhaust gas regulations, the need for CO2 reduction has increased. In order to achieve both lower emissions and lower CO2, we have developed the new combustion system, TVCR by changing from the current mechanical fuel injection system to electrical fuel injection system and designing the optimal combustion chamber shape. This article describes the development of the optimal combustion chamber shape for TVCR and an approach that maintains installation compatibility equivalent to that of current models.

- D902

- IDI Combustion

- TVCR

- Small Cylinder Bore

- Compactness

- Electronic Control

- 【Related SDGs】

-

Development of Hydraulic System for 3-Ton Class Mini Excavator “U-30/35-6α Series”Construction Machinery Base Technology Engineering Dept.Construction Machinery Engineering Dept. for Excavator

The 3–3.5-ton class mini excavators are crucial conventional products shipped worldwide. The mini excavator U-30/35 series, is a main model, especially for Japanese market; however, there has been growing discontent at its work capacity due to its decreasing engine output with emission regulations. Recently, excavators are required to comply with energy-saving regulations to ptotect the environment. In addition, excavators are required to improve operability due to the increasing number of poor operators. To address these problems, we have developed a novel hydraulic system for the mini excavator U-30/35-6a series. We have achieved energy conservation, including improved work capacity and operability, by adopting a 1-pump load sensing (1pLS) system with a swivel priority circuit.

- Mini Excavator

- Load Sensing

- Swivel Priority Circuit

- 【Related SDGs】

-

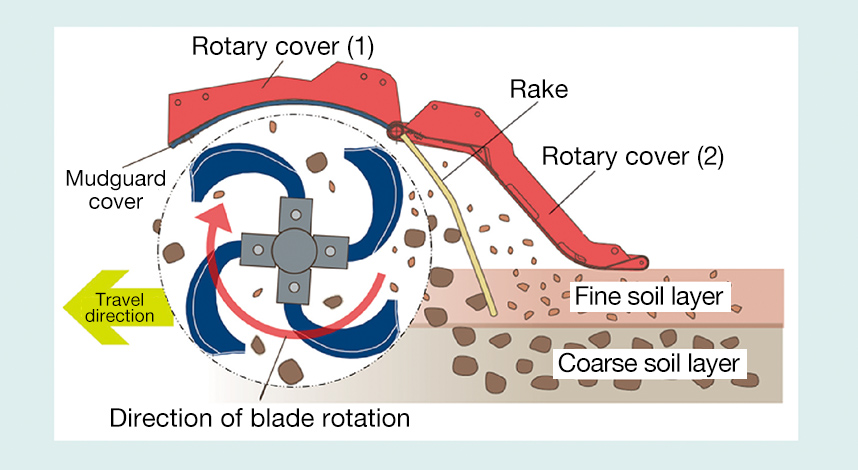

Development of Rotary for Upland Farming with SL Series Tractor for the Domestic MarketFarm Machinery Implements and Products Engineering Dept.

In response to the recent decline in rice prices in Japan, a growing number of rice farmers are transitioning to upland farming. This trend has been further amplified by the Japanese government's policy initiatives aimed at expanding the acreage and production of upland crops. Consequently, the focus of the domestic agricultural machinery market has shifted from catering primarily to rice farming needs to addressing the demands of upland farming practices. To address this market transformation, we have developed the "Up-cut rotary tiller" and the "Riding rotary tiller," specifically engineered to enhance performance and work efficiency in upland farming applications. These innovative tillers make substantial contributions to improving both performance and work efficiency. Furthermore, their lightweight design facilitates stable operation with the SL series tractor, a model specifically designed for the domestic market.

- Upland Farming

- Rotary Tiller

- SL Series Tractor

- Up-Cut

- Ridging

- 【Related SDGs】

-

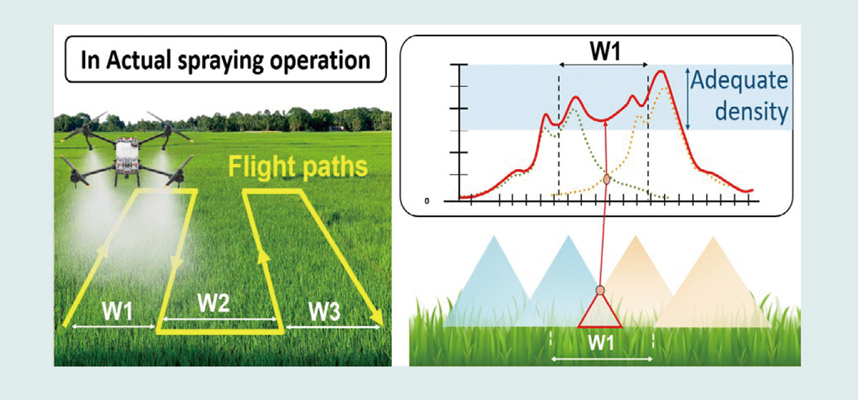

Development of Drone Sprayer and Kubota IoT Intelligence Drone (K-iDrone)KUBOTA Research and Development Asia Co.,Ltd

Agricultural spraying drones have become an important aspect of agricultural industry in recent years. However, these drones are characterized by their technological complexity and sophistication, posing challenges for their effective utilization. Recognizing the inherent IoT nature of drones, KRDA has developed K-iDrone, a cloud-based IoT platform designed to empower users to enhance their work efficiency and refine drone operations by leveraging the power of advanced algorithms and analytical modules to extract actionable insights from data acquired from the drones. Owing to the rapid increase in spraying drones, KRDA has introduced the K-iDrone with the dual objectives of enabling users to harness the full potential of these drones and positioning KUBOTA as a key differentiator in driving the growth potential of spraying drones across Thailand and the ASEAN region.

- Agricultural Spraying Drones

- IoT Platform

- Cloud-Based

- Analytics

- Efficiency Improvement

- 【Related SDGs】

-

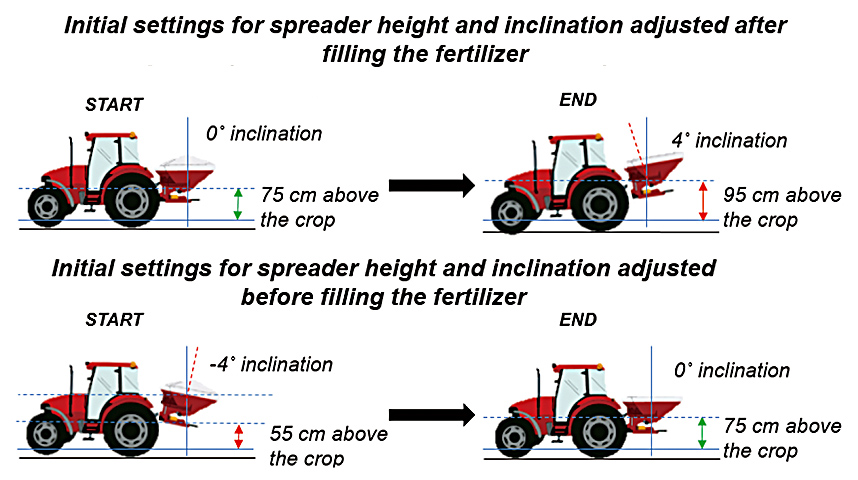

Development of TIM Rear Top Linkage and TIM SpreaderKubota Research and Development Europe S.A.S.

Spreading fertilizer is a crucial aspect of crop production, and it requires precision and efficiency to achieve optimal crop yields. Optimal and accurate distribution of the fertilizer material is highly desired to minimize waste, reduce input costs, maximize return on the crop (prevent underdosing and overdosing of the fertilizer), and minimize environmental impact. To achieve the desired optimization during spreading, Kubota has enhanced the automation of the tractorspreader coupling with Tractor Implement Management (TIM) technology. In addition, Kubota has developed an exclusive novel TIM style function to control the Rear Top Linkage, thereby enabling precise management of the spreading inclination. These advancements, coupled with an optimal spreader control algorithm, have resulted in optimized fertilizer consumption, improved crop yields, and reduced operator fatigue.

- TIM

- Top Link Length Control

- Inclination Control

- Autonomous Spreading

- Pitch Control

- Hitch Control

- 【Related SDGs】

-

Development of PUDAMA - A Spot Fertilizing System for Maize SeedersKverneland Group Soest GmbH

From the view point of sustainability, in many countries there is a necessity laws that restrict the usage offertilizers in crop production, which may result in loweryields, less food and less income of farmers. To overcome this challenging situation, farmers require high-efficient machinery to guaranty high yields and sufficient income. Pudama is a newly-developed spot fertilizing system for maize seeding, which replaces a conventional continuous fertilizer placement. Pudama creates a fertilizer depot, which is precisely aligned to the single maize seed. As a result, the fertilizer is more easily accessible for maize roots in a higher concentration. This allows reducing fertilizer application rate by 25 % without any decrease of yield. This result was proven in field test in several locations over 3 years. The additional cost of Pudama techniques pays off after 2 years and saves on top 40,000€ for the farmer related to the fiscal lifetime of the machine under European conditions. Furthermore, this significant fertilizer reduction helps mitigate climate damage by brown energy input and reducing the risk of fertilizer trickling off into groundwater. Pudama is a unique and sustainable solution on the market; it is compatible with several Optima precision seeders that Soest is producing. This is an important step forward to increase market share and turnover for Kverneland Soest.

- High Speed Planter

- Spot-Fertilizing

- Pressure System

- Fertilizer Savings

- 【Related SDGs】

-

Water & Environment

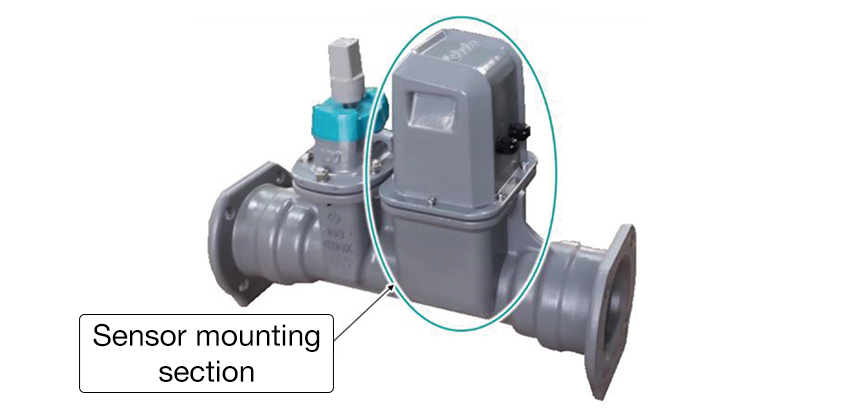

Development of “WATER PIPE COM”, Equipment for Monitoring in Water PipePipe Systems Networks R&D Dept. / Pipe Systems Quality Assurance Dept.Water and Environment R&D Dept. Ⅱ

In an ongoing effort to enhance operational efficiency across various stages of their operations, including planning, construction, and maintenance management, water utilities are constantly seeking innovative solutions. Among these tasks, we have focused specifically on pipeline maintenance and management, conducting in-depth interviews with water utilities to identify key challenges and potential countermeasures. Consequently, a critical challenges identified is the need to garner a deeper understanding of the internal conditions of pipelines. By visualizing information such as hydraulics (flow direction, velocity, and water pressure) and water quality parameters (residual chlorine concentration, turbidity, and water temperature), water utilities can significantly improve the efficiency of their maintenance activities. To achieve this objective, it is essential to gather comprehensive pipeline data from multiple points and manage it centrally. With this in mind, we are exploring the potential of valves, which are ubiquitous components in water pipelines. We are currently developing a device with an integrated sensing function for resilient seated sluice valves (product name: WATER PIPE COM) and associated communication equipment.

- Monitoring

- Multi-Point Measurement

- Resilient Seated Gate Valve

- Sensor Installation Part

- Sensor Maintenance Method

- Flow Direction/Velocity Sensor

- Communication Device

- 【Related SDGs】

-

Development of Rotating Panel Filter for Membrane Bio-ReactorWater Circulation Engineering Design Dept. / Membrane Systems Dept.Water Circulation Engineering Dept.

Membrane Bio-Reactor (MBR) produce high-quality effluent while requiring a relatively small footprint. However, stable operation of MBR depends on effective pretreatment. Although 1-mm spacing bar screens have been widely employed as MBR pretreatment in Japan, their limited debris removal capability can lead to the accumulation of debris on the membrane, compromising its performance. To address this challenge, Kubota has developed a novel screening system for MBR that offers superior debris removal, space efficiency, and cost-effectiveness. This innovative system utilizes mesh material as a screening element, achieving both high removal efficiency and high throughput. The combined structure of the mesh and support frame ensures extended screen life, while the integrated high-pressure cleaning system maintains filtration sustainability. By employing this advanced screening system, MBR operations can be stabilized even for sewage treatment plants faced with high debris concentrations in their influent.

- Membrane Bio-Reactor

- MBR

- Sewage Treatment

- Micro Screen

- Rotating Panel Filter

- 【Related SDGs】

-

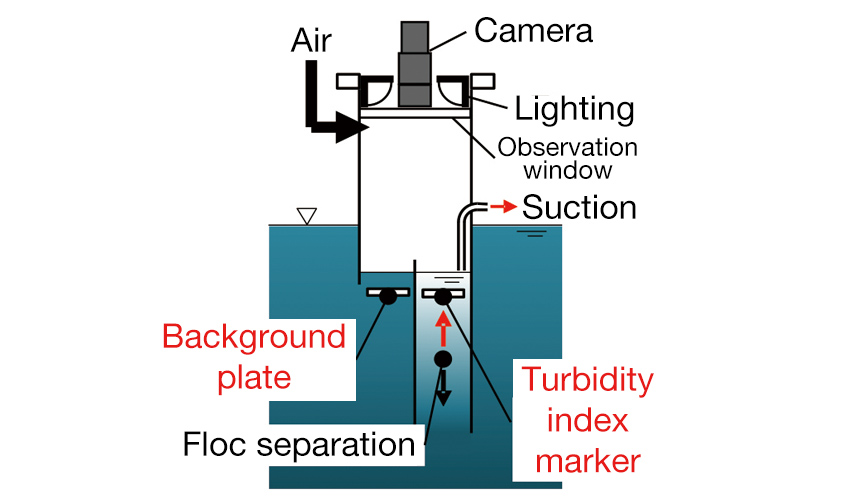

Development of Flocculation Sensor for Industrial Wastewater TreatmentWater and Environment R&D Dept. ⅡKUBOTA Environmental Engineering Corporation

The flocculation method, a widely employed treatment technology for industrial wastewater purification, poses challenges for customers, including water quality deterioration due to inefficient flocculation, rising costs associated with excessive chemical addition, and the need for maintenance personnel for operational management. To address these issues, we have developed a groundbreaking sensor that utilizes image diagnostics technology to achieve human-like sensing capabilities, setting it apart from conventional aggregation sensors that employ light transmission and scattering techniques. The implementation of this sensor can address customerfacing challenges, foster IoT adoption in the industrial wastewater treatment sector, and contribute to the expansion of Kubota's industrial wastewater treatment business.

- Flocculation

- Flocculation Sensor

- Image Diagnosis

- Operation and Maintenance

- 【Related SDGs】

-

Development of All-plastic FlangeKubota ChemiX Co., Ltd.

Steel pipes, commonly employed as piping materials in various industrial settings, are susceptible to corrosion over time. To address this issue, Kubota Chemix (KC) has embarked on an initiative to expand its market presence by proposing plastic pipes as an alternative solution. However, even with plastic piping, the flanges used to connect valves and other components are typically made of metal, posing challenges in terms of corrosion resistance and processing. In the 2020 technical report, we presented an analysis of the shape of resin flanges. This report focused on the development of a resin flange that exhibits enhanced strength and workability via improvements in product design and mold optimization.

- Pressured Pipeline

- Flange

- Fiber-Reinforced Resin

- Corrosion

- 【Related SDGs】

-

Introduction Article

- Introduction of Kubota Research & Development North America (KRDNA)

- Introduction of Large-Scale MBR Operation Case at Nakahama Sewage Treatment Plant, Osaka City

- Introduction of ASB System and Its Effects on Night Soil Treatment

New Products

- Ultralight Drainage Pump for Drainage Pump Vehicle