KUBOTA TECHNICAL REPORT No.54 JANUARY 2021

Kubota delivers products that solve social issues in the areas of food, water, and the environment, enriching people’s lives.The global community is expected to become increasingly complex and our customers’ business environment will change even more.It is with this in mind that we have developed a new five-year Medium-Term Business Plan that kicks off this year. Guided by the new Business Plan, we wish to be a company that offers total solutions to such issues by combining our proprietary technologies, products, and services.We will continue to provide new value in the fields of food, water, and the environment through innovations that are essential for this purpose. We hope you will enjoy reading Kubota Technical Report No. 54, which collects a variety of technological developments in each field.

Farm & Industrial Machinery

Development of AgriRobo Tractor MR1000AAgricultural Tractor Engineering Dept. / Advanced Systems R&D Dept. Ⅰ / Vehicle Base Technology Engineering Dept.

Japan’s working population engaged in agriculture is declining due to the aging of farmers. As a result, the labor shortage is becoming more serious. On the other hand, farmland consolidation and scale expansion by certified farmers are increasing, and labor saving and efficiency improvement are required. To solve these problems, Kubota is promoting the development of smart agricultural technology. Kubota has already released into the market tractors, combine harvesters and rice transplanters with an autonomous driving system. To adapt to the needs of certified farmers we developed the new AgriRobo tractor “MR1000A”, which is larger and more versatile than conventional AgriRobo tractors. Here we show the technical development of “MR1000A”.

- Smart-agriculture

- Tractor

- Autonomous

- Control

- Detection System

- GNSS

- 【Related SDGs】

-

Development of the Head-feeding Combine Harvester DR6130A for Domestic MarketCombine Harvester Engineering Dept.

In Japan’s agriculture, farmland consolidation has accelerated due to a decline in the number of farms as a result of the aging of the population and the abandonment of farming. As the area of cultivated fields per farm increases, agricultural machinery is required to further improve work efficiency and save manpower and labor. To respond to such exigencies, Kubota has developed the Head-Feeding combine harvester “DR 6130 A” equipped with a large 130 horsepower engine. The harvester features an automatic operation assist function in addition to a major improvement in work efficiency. This paper describes ① the development of a thresher with improved crop adaptability, ② improvement of cleanability brought about by the side plate opening mechanism of the grain tank, ③ the automatic operation assist function.

- Combine Harvester

- Adaptability

- Cleanability

- Autonomous Driving

- Driving Control

- 【Related SDGs】

-

Development of Small Rice Transplanter AW Series Transplanter Engineering Dept.

Although the total demand for rice transplanters in Japan is declining, the ratio of small-sized rice transplanters is an important class that continues to maintain about a 40% share of the market. Kubota has developed the AW series of fully remodeled machines with the aim of increasing the motivation of small machine users to continue rice cultivation and maintaining and expanding the business volume and market share of Kubota rice transplanters overall. Smallscale farmers who are small machine users are part-time farmers with a particularly high proportion of elderly people, who are consequently unfamiliar with machinery. Therefore, the rice transplanter was equipped with many automation functions based on the concept of simplicity, security, and comfort. This paper introduces ① development of addition of “Super Yu Yu Turn” to our line of small class machines and ② development technology of the lightest machine in its class.

- Rice Transplanter

- Automation

- Small-scale Farmer

- Simplicity・Security・Comfort

- 【Related SDGs】

-

Development of T90 Series Lawn Tractor for North AmericaTurf Engineering Department North America / Turf Engineering Department

Through Kubota’s market surveys, it was determined that despite the growing popularity of zero- turn mowers, there is still a large consumer base for lawn tractors in North America. Because of this, the T90-Series lawn tractor was developed as an updated version of the T80-Series. Over time, many of Kubota’s competitors surpassed the T80-Series in performance and specifications. Therefore, the challenge of the design team was to create a high-quality lawn tractor that exceeded the performance of competitor machines and reignite sales of the T-Series. By redesigning almost every aspect of the T80-Series including the frame, engine, mower decks, steering and operator controls we were able to achieve our goal. Once the new T90-Series was introduced into the market in 2018, sales for the T-Series lawn tractors more than doubled compared to 2017 total sales.

- Lawn Tractor

- Performance

- Turning Radius

- Comfort

- 【Related SDGs】

-

Development of Two-stage Snow Blower SLA-1070STFarm Machinery Implements and Products Engineering Dept. / Farm and Industrial Machinery R&D Dept. Ⅱ

In cold regions of Japan with heavy snowfall, snow removal work during the winter months is extremely hard work. With the mechanization of snow removal work, the use of Two-stage snow blower has become common in ordinary households that used to remove snow with shovels. Kubota also developed the Snow Slalom Series of Two-stage snow blower in 2016, and sales have been increasing steadily. However, snow removal work is often done early in the morning before going to work, and it is necessary to consider the effect of noise on neighboring residents. In addition, a user who is unfamiliar with machine operation is prone to hitting the snow blower against the curb during snow removal, and breaking the shear bolt of the snow removal section (bolt that protects the power transmission system of the snow removal section) , and therefore having to replace the shear bolt in cold weather. To solves these problems, Kubota has developed the Snow Slalom SLA-1070ST, which is equipped with a mechanism to reduce noise and mitigate the impact even if it hits the snow removal section.

- Two-stage Snow Blower

- Snow Slalom

- Engine Cover

- Blower Noise Reduction

- Torque Limiter

- 【Related SDGs】

-

Development of Spinach Conditioner NC301Post-Harvest Products Engineering Dept.

Processing of soft leafy vegetables such as spinach (removal of unnecessary roots, cotyledons, and lower leaves) accounts for 44%1) of the total working hours (from seeding to shipping), and the work is carried out by employed workers. On the other hand, since the processing of soft leafy vegetables requires delicate handling, there is a conventional machine for this purpose, but it has been difficult to save labor by mechanization. Therefore, we aimed to reduce the labor component of manual processing and improve work efficiency by maximizing the root cutting accuracy and the cotyledon and lower leaf removal rate by developing a machine for this task. This paper describes the features and processing work performed by the spinach conditioner. At the same time, we will introduce the development technology.

- Spinach

- Soft Leafy Vegetables

- Processing

- Removal of Lower Leaves

- Removal of Cotyledons

- High Efficiency

- 【Related SDGs】

-

Development of MU4902 Tractor for ASEAN MarketKUBOTA Research and Development Asia Co., Ltd.

In recent years, under the policy of the government, the transition from rice cultivation to dry crop cultivation was making progress in Thailand. While rice has been the largest harvested area by crop, the harvest area occupied dry crops (sugar cane, cassava, corn) is expected to increase due to the Thai government encouraging farmers to change to crops other than rice and also the growing demand for bioethanol. As a result, there has been an increasing demand for heavyweight tractors for dry field farming away from conventional lightweight tractors used in paddy fields. Moreover, looking at other ASEAN countries, in Cambodia, in addition to the two consecutive seasons of rice cultivation (dry field / paddy field), cassava was also a major crop. In Myanmar and Laos, in addition to rice (dry rice fields), beans and cassava were major crops. It was thought that the market for heavyweight tractors for dry crops was expanding. Against this background, KUBOTA Research and Development Asia (KRDA) has developed a tractor for ASEAN dry-crop farming. Clarify the tractor specifications required for ASEAN dry-crop farming tasks and introduce the required development technology.

- Heavyweight Tractor

- Dry Field

- Operating Speed

- Fuel Consumption

- Local Development

- 【Related SDGs】

-

Development of a High Speed PlanterR&D KVG Soest

Climate change and in consequence a shorter time period for optimum planting conditions demanding an efficient solution. Instead of using more planters the possibility to improve situation, is a machine, which is able to plant at high speed. Hence development of high speed planter was required and the traditional speed range of 7 to 9 km/h was raised up to 18km/h. Beside the speed target higher precision in respect of spacing (planting distance from one seed to the other) was achieved. To reach this task the Optima planter was changed from a vacuum system to a pressure system. The new system, Optima SX, is highly efficient and does not need complicated techniques. By increasing the working speed customers get 30 to 40 % more efficiency without additional resources. A high level of standardization puts KVG in a position to reach proper margin at attractive prices for our customers.

- High Speed Planter

- Spacing

- Interrupter

- Pressure System

- Vacuum System

- 【Related SDGs】

-

Development of SL Series Tractor with “Keeping Straight Function” Compact Tractor Engineering Dept. / Farm and Industrial Machinery R&D Dept. Ⅰ

KUBOTA released a new lightweight tractor with the “Keeping Straight Function” in Jan. 2020, in response to an increased demand for labor saving and efficiency in the farming sector. This new model SL series tractor features the “GS” specification (“GS” stands for “Go Straight”, Keeping Straight Function). This model satisfies the needs of a broad range of customers by providing an enhanced range of options that enrich the line-up such as a cabin model, ROPS model, power crawler model, wheel model in 21-44kW (28-60 PS), and by supporting multiple implements. This paper describes the new technology added to the model.

- Robot

- Automatic Steering

- GNSS

- 【Related SDGs】

-

Development of 03・07・V3 StageV EnginesEngine Engineering Dept.

Our leading product, 03・07・V3 series which are Kubota vertical water-cooled diesel engines covering the power range of 19-56 kW are installed on many machines. In Europe, where these engines have penetrated the market, a new emission regulation (StageV) came into effect from 2019. Accordingly, we have developed new models that comply with StageV and improved product appeal in response to customer’s requests for conventional models. Here we describe our approach to meeting customer’s requests by expanding the line-up, and by decreasing downtime.

- StageV

- Expansion of Engine Line

- Increase in Engine Output

- Decreasing Downtime

- DPF

- 【Related SDGs】

-

Development of Catalyst Technology for Particle Number RegulationEngine Engineering Dept.

In order to resolve the environmental problem of emissions in to the atmosphere, the emission regulations on harmful components in exhaust gas from diesel engines are being strengthened year by year. Especially, in the EU, particulate number (PN) regulations were implemented from StageV for non-road diesel engines. In order to comply with PN regulations, it is necessary to improve the diesel particulate filter (DPF) performance in collecting the particulate matter (PM) from diesel engines. In our development, we achieved compliance with the PN regulations by improving the substrate and the catalyst of the DPF which are related to the collecting performance and combustibility of PM, without any degradation in engine performance and mountability.

- Air Pollution Reduction

- Diesel Engine

- PM2.5

- Particulate Number (PN) Regulation

- Exhaust Gas Treatment System

- Diesel Particulate Filter (DPF)

- 【Related SDGs】

-

Development of the CTL SVL65-2 for North AmericaConstruction Machinery Engineering Dept.for Loader / Kubota North America Corp.

A compact track loader (CTL) is a compact construction machine that is used in the North American market. It has good running ability on rough terrain, high mobility and versatility. In addition, it can perform a wide variety of attachment tasks. In recent years, this market has continued to expand, and Kubota has also steadily expanded its sales volume since launching the CTL in 2010. This time, Kubota released the SVL65-2, the lightest in the Kubota range in order to expand CTL’s product line. Its weight is significantly reduced while maintaining excellent habitability as good as that of SVL75-2, which is the current model in the upper class. Moreover, SVL65-2 can perform smooth simultaneous movements of loader arm, bucket, and AUX hydraulics because we developed a highly evolved hydraulic circuit and an advanced multifunction valve that are superior to those of the SVL75-2.

- Compact Track Loader

- Weight Reduction

- Advanced Multifunction Valve

- 【Related SDGs】

-

Development of Stand-On Type Mini Compact Track Loader SCL1000Great Plains Manufacturing, LP Engineering

The SCL 1000 is Kubota’s entry into the growing market of Compact Utility Loaders (CUL). A CUL, also known as a stand-on skid steer, is a power unit that has the ability to work in tighter spaces than a traditional skid steer or compact track loader. In North America, the CUL market is growing rapidly for both commercial and rental applications, replacing traditional skid steers on some job sites. This market is new for Kubota and the natural desire to exceed the features of competitor machines led to several technical challenges. The key features that add value to Kubota’s SCL 1000 are wide tracks on a narrow frame, a 25 Hp turbocharged engine, light machine with high ROC (rated operating capacity) and vertical lift plus operator features such as comfort and control logic.

- Compact Utility Loaders

- Stand-on Skid Steer

- Wide Tracks

- High ROC

- 【Related SDGs】

-

Development of Weathering Evaluation TechnologyMaterials Center

In recent years, in addition to a product’s work performance, a quality appearance is becoming an important evaluation point for users of both agricultural and construction machinery. Among them, the weather resistance of the coating is the most important factor for retaining a quality appearance. In order to prevent deterioration of the appearance of products that are used over an extended period of time, it is important to examine the types of coating, and the coating systems, and furthermore to evaluate the durability (weatherability) correctly. However, since a long-term outdoor exposure test takes too much time, it is necessary to perform an accelerated test that is highly correlated with outdoor exposure. This time, we have defined a unique KUBOTA accelerated test method by examining the test conditions using a xenon accelerated testing apparatus.

- Coatings

- Appearance Quality

- Weatherability

- Outdoor Exposure

- Accelerated Test

- 【Related SDGs】

-

Water & Environment

Development of Flangeless T-pipes and Isolating ValvesPipe Systems Networks R&D Dept. / Intellectual Property Dept.

A lot of damage to T-pipes located in water pipelines have been reported in investigations conducted after the 2011 Tohoku earthquake and 2016 Kumamoto earthquake. On the other hand, the use of earthquake-resistant joints has become widespread, but conventional flange joints are still predominantly used where the T-pipe branch joins another pipe. It was thought that the cause of the damage was that the joint strength and water tightness required during earthquake was insufficient. Isolating valves have to be replaced when performance deterioration occurs because these valves are vitally important in order to cut off water pressure in an emergency. That being the case, large-scale construction works were needed, and consequently there are some issues related to construction. In order to address these issues, we developed flangeless T-pipes and isolating valves with high-strength joints sufficient to resist an earthquake and with an easy valve replacement function.

- T-pipe

- Isolating Valve

- Flangeless Joint

- Lateral Load

- High Pressure Water Sealing Performance

- Construction Method for Replacing Isolating Valve

- 【Related SDGs】

-

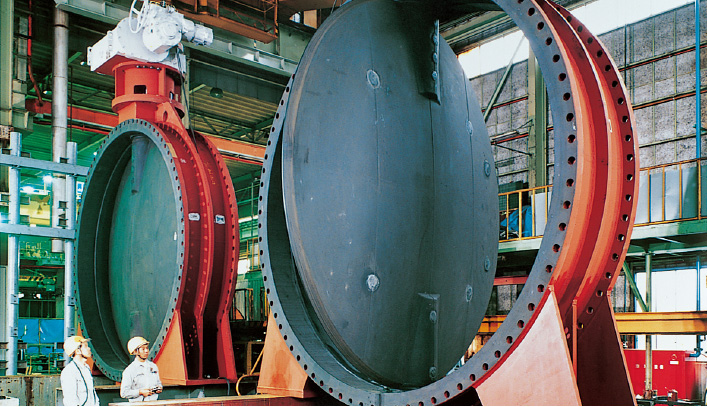

Development of Diagnostic Technology for Special Gate Valve for Petrochemical PlantPumps and Valves Manufacturing Dept. / Advanced Systems R&D Center

Special gate valves for petrochemical plants (hereinafter, SG-V) are the main export products of the valve business, and only two companies globally have been licensed by U.S. Lummus Technology to use the Catofin ® Process. The company has so far supplied products to 14 plants in 6 countries with a global share of 60%. In recent years, in concert with the increase in the number of years of plant operation, preventive maintenance activities to minimize the product life cycle cost have been increasing. This report describes efforts to develop diagnostic technology to diagnose the condition of the valve while the plant is in operation and to perform appropriate maintenance at an appropriate time.

- Petrochemical Plant

- Diagnostic

- Preventive Maintenance

- High Temperature

- 【Related SDGs】

-

Development of Combustion Analysis Technologies for Municipal Waste IncineratorWater and Environment R&D Dept. Ⅰ / Water and Environment R&D Dept. Ⅲ KUBOTA ENVIROMENTAL SERVICE CO.,LTD.Solid Waste Engineering Dept.

In order to develop a municipal waste incinerator which met the customer requirement for rapidly reducing the environmental burden and lifecycle cost (LCC), utilizing combustion analysis technologies has been imperative. However, there were two problems in conducting combustion analysis. First, it was impossible to take into account several hundred combustion reactions that take place inside an incinerator. Second, 3D numerical analysis, which was necessary to examine the performance of the actual incinerators, requires huge computational resources. To solve these problems, identifying the main combustion reactions and choosing an adequate numerical combustion model were conducted based on the results of a refuse-derived fuel (RDF) combustion test in the experimental reactor. As a result, it was found that 3D numerical analysis could be applied in incinerator design. The validation results for this combustion analysis method in an actual incinerator test are also described in this article.

- Municipal Waste Incinerator

- Combustion Analysis

- Combustion Reaction

- Combustion Test

- Three-dimensional Analysis

- 【Related SDGs】

-

Development of the Full-speed, Any-water Level Operation Function and Diagnostic Function for Pump Gate SystemWater and Environment R&D Dept. Ⅰ

In recent years, flood damage due to localized torrential rain has increased. As urgent action is required, integrating the pump gate that contains the drainage pumps with the water stop gate in an existing waterway is attracting attention because of the advantages of shortening the construction period and reducing costs. On the other hand, depending on the conditions, the pump gate has the following problems: the water level fluctuates over a wide range and the frequency of operation suspension becomes excessive, water cannot be stored in fine weather, and management operations cannot be performed. Kubota has contributed to the widespread use of pump gates, but has developed new functions to solve these problems and to provide more reliable equipment. In this paper, we introduce the details and effectiveness of the developed full-speed, any-water level operation function and the diagnostic function that can ascertain the soundness of the pump in idle operation.

- Localized Torrential Rain

- Flood Prevention

- Pump Gate System

- Submergible Pump

- Management Operation

- 【Related SDGs】

-

Development of FILCERA HD -Ceramic Membrane Filtration Equipment for Drinking Water Treatment PlantsWater and Environment R&D Dept. Ⅱ / Water and Environment R&D Dept. Ⅰ / Environmental Engineering Design and Procurement Dept. / Water and Environmental Solutions Developing and Sales Dept.

Water treatment plants using river surface water as raw water have found it necessary in recent years to cope with the rapid changes in the turbidity of raw water due to climate change. After the Great East Japan Earthquake, the importance of preparing for large-scale earthquakes has also been emphasized. At the same time, the declining population has led to a decline in water bill revenues and a shortage of technical staff. Against this backdrop, the Ministry of Health, Labour and Welfare has set “safety” “resilience” and “sustainability” as the ideal image of water supply in its new water supply vision. To achieve it, we have developed ceramic membrane filtration equipment (FILCERA HD) with dramatically improved responsiveness to changes in the turbidity of raw water. This equipment takes advantage of the characteristic of the membrane filtration method, which facilitates the automation of water treatment. This paper introduces the design concept, performance and durability evaluation.

- Water Purification

- Ceramic Membrane

- Membrane Filtration

- High Turbidity

- Stable Operation

- Backwash

- Durability

- Earthquake Resistance

- 【Related SDGs】

-

Development of Plastic Single Stack Drain FittingKubota ChemiX Co., Ltd. R&D Dept.

The construction industry faces many challenges such as soaring labor costs due to labor shortages, aging skilled workers, and reduction of construction costs. To solve these problems, the Group has been working on the development of cast iron single stack drain fitting and resin drainage vertical pipes with a fire spread prevention function. As a result, it has become possible to use inexpensive and easy-to-install PVC pipes for vertical and horizontal drainage pipes. In recent years, the needs of the market have further advanced, and there has been a demand for plasticization of all drainage pipes, including plasticization of cast iron single stack drain fittings penetrating the fire protection section. In this paper, we report on the development of a plastic single stack drain fitting with the aim of making the drainage pipes all-plastic.

- Drain Pipe

- Fire Resistance

- Fire Compartment

- Sound Insulation

- 【Related SDGs】

-

Introduction Article

- Introduction of Drainage Pump Vehicles to Assist Restoration Work Following Severe Flooding

- Introduction of Waste Treatment Operation at the Volume Reduction Facility of Futaba Town

New Products

- Highly Packed KUBOTA Submerged Membrane Unit SP900-A