Environmental Recycling

Creating new value from the waste generated in human activity

Kubota began environmental recycling business in the 1950s, when it began manufacturing shredders for the ore extracted in mining. As people's lives become more affluent, the waste generated from these lifestyles become a major social issue. Kubota began working on night soil treatment technology through water treatment, and waste incineration technology based on its experience in combustion technology. Through further streamlining the crushing, sorting, incineration, and melting processes, as well as the establishment of technologies to recycle resources from waste that had previously been disposed of, we aim to realize a circular society that will continue to enrich people's lives.

Contributing to the waste treatment,

which is essential to society

The waste treatment that is an inevitable part of human lifestyles is essential for today’s society. We must perform the safe and stable processing of the waste material that is generated 365 days a year. This requires time and effort, as well as the development of technology that is appropriate for the times. Kubota has built a solid position with a series of solutions for waste treatment and recycling, including shredding, sorting, incineration, and melting. In order to continue to meet the growing needs of our customers, Kubota will continue to pursue the realization of a recycling process that will allow us to treat more waste and create new resources from it.

Waste treatment and maintenance demanded in the advanced economic society of Japan

For more than 60 years, Kubota have been dealing with waste disposal issues that have arisen in Japan's advanced economic society through the construction, management, and operation of recycling facilities including shredders and sorting machines, and waste treatment facilities represented by waste incinerators and melting furnaces.

Moving forward together with the growth and

development of society

Kubota began environmental recycling business in the 1950s, when it began manufacturing shredders to shred the ore extracted in mining. In the 1960s, as life became more prosperous and cities became more congested, the waste material generated from that lifestyle began to become a major social issue. Kubota began to work on environmental recycling businesses such as the municipal waste incinerator, utilizing the experience it had gained in developing technology for night soil and sewage treatment, and in combustion technology.

Contributing to the solution of social issues with accumulated technologies

Working based on the stoker (combustion equipment) technology that Kubota had accumulated since the Taisho era, we developed a mechanized batch combustion type incinerator and delivered the first system to the city of Aomori in 1964. Later, as the population concentrated in urban areas and the standard of living improved, urban waste became higher in calorie content, and even local cities began to require high-temperature combustion equipment of the metropolitan type. Kubota has made a contribution by combining the technologies required in line with the changes in the waste treatment. For example, the introduction and practical application of technology from the Swiss company K+K for large, completely continuous furnaces made it possible to receive orders for large-scale incineration plants with generators and boilers for large cities.

Providing non-stop operations so that society can

continue tomorrow

A feature of Kubota's environmental recycling business is that it implements a series of processes that efficiently treat a variety of wastes into valuable materials again. In addition to giving the equipment itself high durability so that it can continuously process the waste materials generated in our daily lives, Kubota also realizes stable operations with its abundant past results in the operational aspects such as knowing how waste materials should be treated.

The 14-year challenge of fully recycling waste materials to restore a beautiful island

In the 1980s, the illegal dumping of industrial waste occurred on Teshima Island in Kagawa Prefecture. To restore the beautiful island environment, Kubota took on the business of digging up the buried waste and reprocessing it. The level of safety and security required was unprecedented in the industry, such as a requirement to constantly disclose the processing situation 24 hours a day, 365 days a year, but Kubota continued working over 14 years to process the enormous amount of waste, which totaled around 900,000 tons. Kubota has also contributed to the maintenance of a beautiful environment after the processing, with water treatment technology that is used to purify the groundwater that was contaminated by the dumped waste.

Aiming to create a Resource Circulation Society that is

tailored to each different situation

Wherever we look in the world, there is no deviation from the general direction of working to reuse our limited resources. However, there are great differences between countries regarding the systems of recycling. The types and amounts of waste materials generated vary between countries, so each country selects the processing methods appropriate for its own situation. It is expected that the demand for waste treatment will increase from now on, such as in Asia, where household appliances are increasingly being recycled, and in Europe, where there is a high awareness of the environment in areas such as resource recovery. Kubota will use solutions that combine its series of technologies for shredding, sorting, incineration and melting as a core foundation to contribute to the realization of resource circulation societies that are tailored to each region and society.

Deep recycling technology to realize a resource circulation society

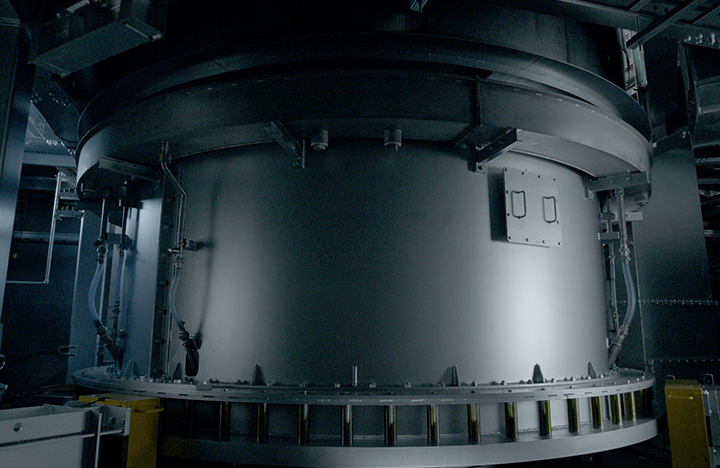

Kubota is taking on the challenge of waste processing that has not yet been realized. This is deep recycling technology that aims to process the waste material sent to final disposal sites, to extract even more valuable material and return it to society. The key to achieve this aim is Kubota’s unique surface melting furnace, which melts the incineration ash containing valuable materials, removes any unsorted metal, and extracts the energy generated during melting. In the future, we will realize a circular society by providing solutions that further increase efficiency and profitability.