Kubota's Vision for

Resource Circulation Solutions

Total Solutions that Address Waste Treatment Issues and Contribute to a Resource Circulation Society

As we live our day-to-day lives, we cannot avoid having to dispose of waste. Proper treatment of discharged waste is considered one of the foundations for ensuring public health and a good living environment.

While we seek to achieve a sustainable society in which people can live comfortably, we need to control waste emissions, treat waste properly, and reuse it as resources. However, waste treatment today involves a number of issues, including handling diversifying types of waste, low rates of waste recycling, and a shortage of final disposal sites.

For more than 60 years, to ensure a good living environment and improve public health, Kubota has been grappling with waste treatment issues that continue to change with the times. Using the technology and experience we have gained over the years, we will strive to build a sustainable society that can address issues faced in waste treatment today and achieve resource circulation that places less burden on the environment.

Our Challenge

Issues Involving Waste Treatment Today

Modern waste treatment faces issues stemming from the societal trends of mass production and mass consumption that have accompanied economic development. There have been calls to move away from the linear economy*1, in which resources are extracted to make products that eventually are thrown away, toward a circular economy*2.

- *1.Economic activity with a linear flow of goods in which products are produced from resources, consumed, and then disposed of.

- *2.Economic activity with a circular flow of resources, in which products and raw materials disposed of during production and consumption are recycled. This model seeks to reduce environmental impact by limiting energy consumption and the input of new resources.

- Proper Treatment of Diversifying Waste Materials

-

As economic development and digitization gain traction worldwide, a variety of resources are being consumed, while waste materials today are increasing in variety.

One recent example is the increasing trend of e-waste, the term for discarded electrical and electronic devices. Global production of e-waste increased from 44.4 million tons in 2014 to 53.6 million tons in 2019, and is projected to reach 74 million*3 by 2030. However, e-waste is not being disposed of properly in more than a few regions. The correct treatment of e-waste and various other waste products containing hazardous substances is essential for preventing their adverse impact on the environment and human health.

- *3.United Nations University, "The Global E-waste Monitor 2020".

- Low Recycling Rates for Waste Materials

-

Given the increasing trend in resource consumption and energy demand worldwide, there are calls for a shift from the conventional model of mass production, mass consumption and mass disposing to a circular economy that uses resources in sustainable ways.

Today, valuable metals, rare metals, and other useful metal resources contained in e-waste are referred to as "urban mines", likening them to mines from which metals are extracted. However, the percentage of resources recovered and reused from these urban mines remains low. The global e-waste recycling rate in 2019 was only 17.4%*4.

Realizing a circular economy will require a mechanism for the recovery and reuse of resources from all kinds of waste materials. Particularly in Japan, where energy and metal resources are scarce, efficient recovery and reuse of limited resources is desired.

- *4.United Nations University, "The Global E-waste Monitor 2020".

- Shortage of Final Disposal Sites

-

The term final disposal sites refers to the locations where waste that has not been recycled or reused is landfilled in a safe and controlled manner. The status of such sites in Japan has gradually improved since 1989, when the number of remaining sustainable years was eight; as of 2020, that figure was 22.4 years*5.

Although the number of remaining sustainable years is limited, building new waste disposal sites poses a challenge. In particular, it is difficult to find land in metropolitan areas, and the enormous costs of burying waste at sea presents a high barrier.

- *5.Ministry of the Environment "Municipal Solid Waste Generation and Disposal in FY2020".

Our Approach

Problem-Solving Approach

To find solutions to the issues we are facing and realize a resource circulation society, it is essential to have a system that can properly dispose of all types of waste and convert as much waste as possible into resources. Kubota is applying its many years of technologies and its high-quality products and services toward three problem-solving approaches.

Our Strength

Deploying Kubota's Strengths to Achieve a Circular Economy

Because Kubota has spent over 60 years grappling with waste treatment challenges, our strengths lie in our advanced technologies and high-quality products, as well as our ability to provide these as integrated solutions and ensure stable operations. Kubota is uniquely equipped with waste treatment capabilities, with which we aim to build a resource circulation system.

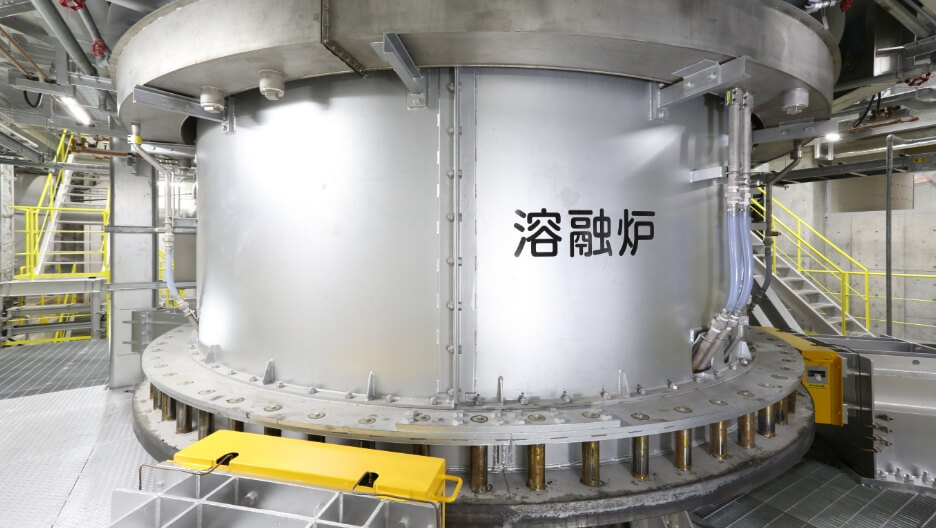

Years of Experience in Shredding, Melting, and Recovery Technologies

With the inauguration of its waterworks research laboratory in 1961, Kubota started research in the treatment of sewage, night soil, and municipal waste. Since then, with the growing emergence of environmental problems associated with economic growth, we have continued to put our efforts into research and development for shredding, melting, and recovery technologies through the introduction of shredder and melting-related technologies from overseas.

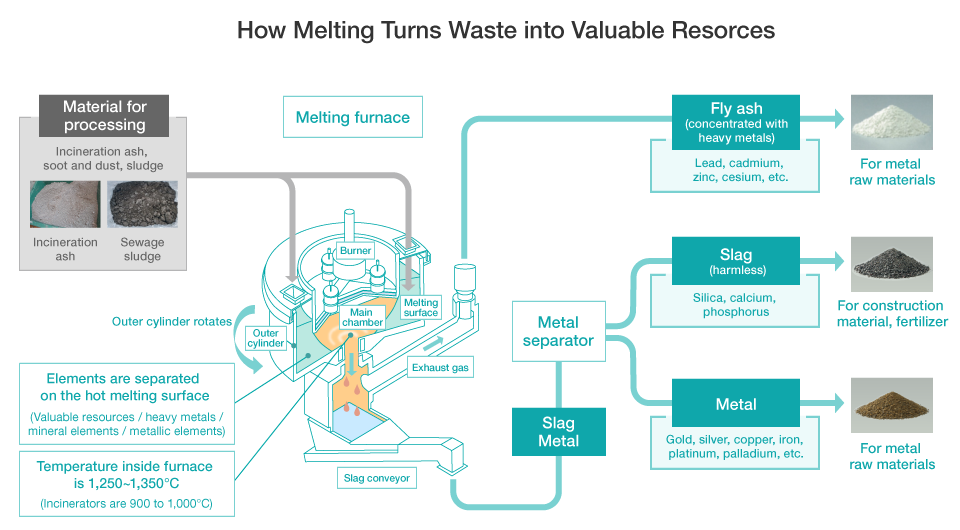

Kubota technologies truly demonstrate their capabilities in the field of melting. Our expertise in the stable operation of melting furnaces that require advanced technologies to operate and manage, along with our exclusive technologies for separating and recovering metals from slag produced through the melting of waste materials, make efficient resource conversion possible.

Track Record of Response to Critical Social Issues

Teshima Island, Kagawa Prefecture, Japan

The island of Teshima in Kawaga Prefecture has for many years been plagued by illegal dumping. More than 900,000 tons of industrial waste has been illegally discarded since the 1980s, and by the 1990s the issue had become a major social problem. The types of waste that had been dumped were unknown, and there was a risk of generating toxic substances during incineration; nevertheless, Kubota was the only company to submit a public bid for processing technologies and set out to completely restore the site.

We publicized the operational data from our melting furnace in real time 24 hours a day, a first*6 in the waste treatment industry. The furnace's outstanding durability and control technologies achieved stable operations 340 days per year. Over thirteen years and nine months, from October 2003 to June 2017, the project successfully converted all of the waste products into resources. The valuable materials produced from this waste were vast in both their volume and their variety, resulting in 470,000 tons of molten slag that contained copper amounting to 650 million yen in market value.

- *6.As of October, 2003.

Futaba Town, Fukushima Prefecture, Japan

The Japanese government has been setting up temporary incinerators since 2014 to process the waste generated by the 2011 Great East Japan Earthquake disaster, and the project is still in progress. Kubota has been a member of a specified joint venture (JV) since March 2020, and has been constructing and operating temporary ash processing and incineration facilities to treat the waste.

These facilities melt incineration ash and dust contaminated with radioactive materials to detoxify them and reduce their volume. Despite the advanced technologies required to process contaminated materials through melting, Kubota continues to operate the facilities in a stable manner.

High-Quality Products that Contribute to Efficient Waste Treatment

Kubota's waste treatment capabilities offer not only advanced technologies, but also a lineup of high-quality products. One example is our shredders, which are known for their durability, the fineness and uniformity of the particles from the waste they shred, as well as the company's thorough after-sales service. These advantages are a huge help to recycling plants that need to constantly accept waste and keep running.

Kubota melting furnaces are also designed for "deep recycling," in which valuable materials are extracted from both municipal and industrial waste and given back to society. This enables material recycling, through which highly concentrated metals are concentrated and recovered from extremely low concentrations of metal in waste materials, as well as production of agricultural fertilizer (phosphorus) from sewage sludge at a recovery rate as high as 90%. What is more, by using waste plastic as auxiliary fuel for the melting furnace, CO2 emissions can be reduced, which contributes to carbon neutrality.

A Full Range of Solutions from Sorting to Recycling

From waste shredding and sorting to treatment and recycling, Kubota can provide both local governments and private businesses a full array of solutions that take advantage of our advanced technologies and high-quality products.

At implementation time, Kubota offers complete design setups for individual plants, including equipment settings and optimized layouts to elicit the best performance from products. Kubota can also provide asset management for sound plant operations based on advanced technologies. One example is the Kubota Group's participation in the construction of the Chikuma Environmental Energy Center, a waste incineration facility in Chikuma City, Nagano Prefecture in Japan, which began operation in 2022. This is contributing to the realization of a waste incineration facility that is safe, secure, and stably operated.

Vision

Kubota's Vision for the Future of Resource Circulation Solutions

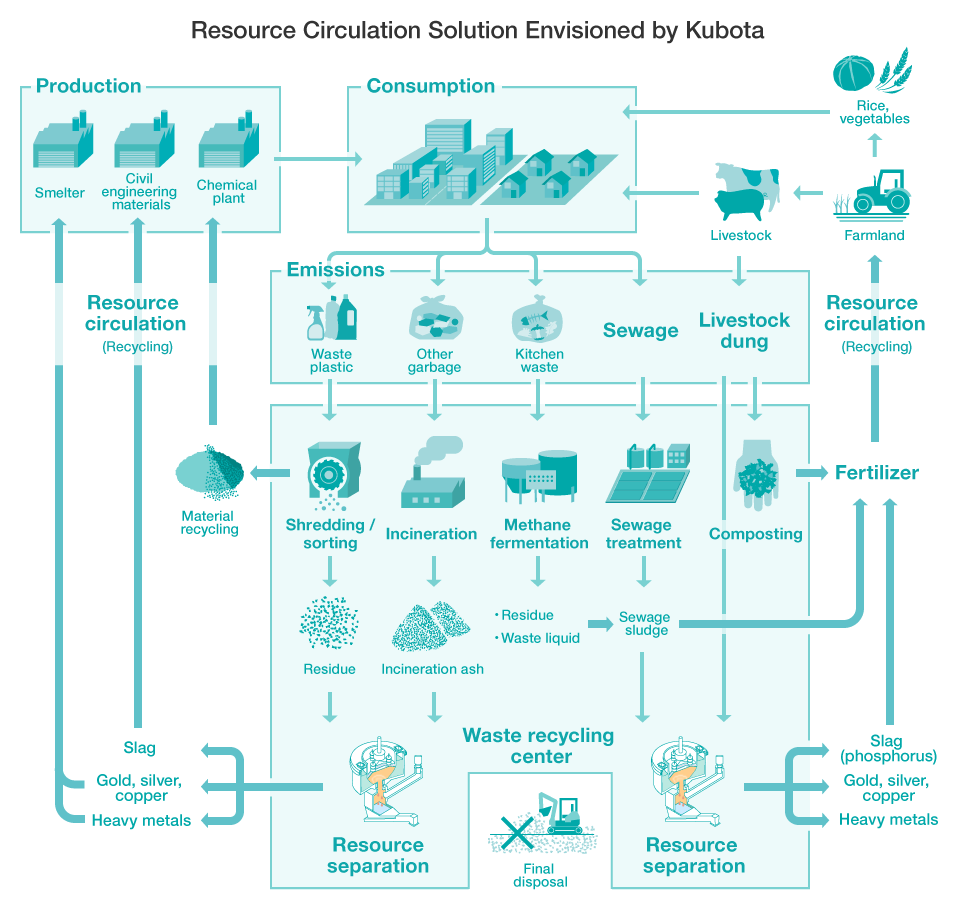

Handling the waste generated through people's activities in society requires a certain amount of cost. However, the waste treatment business has the potential to become an industry that creates valuable resources and generates profits by efficiently shredding and sorting waste, processing it properly, and converting it into resources through melting. Kubota will help to make the circular economy possible by solving problems in waste treatment through resource circulation solutions that utilize its advantages.

The Resource Circulation Solution that we envision as a total solution combines Kubota products and technologies with the technologies, AI and IoT of other companies to circulate all types of waste in the form of energy, fertilizer, and valuable resources. Kubota, in its role as an “Essentials Innovator for Supporting Life,” aims to implement this solution and help to achieve a sustainable society in which people can live in comfort.