Japan’s Heisei era, which lasted from January 1989 to April 2019, is sometimes called the “era of disasters,” and it seems that this trend has continued in the current Reiwa era. Frequent large-scale earthquakes and weather-related disasters are still occurring, and the resulting damage to aging water pipes has affected people’s access to water in many cases. In addition, degradation of finances due to population decline has prompted local governments to promote wide-area cooperation and public-private partnerships for waterworks projects. Water supply is one of the basic forms of social infrastructure that support our daily lives, and there are urgent needs to strengthen water infrastructure, including maintaining and managing water facilities and taking countermeasures against disasters.

To ensure that a safe and reliable water supply can continue, Kubota issued its Manifesto on the Future of Waterworks last year. We asked Takashi Ichikawa, Executive Officer and General Manager of the Pipe Systems Division, about what inspired this manifesto and what it seeks to achieve.

Ensuring Safe and Reliable Water and Waterworks for the Future

Since the 1990s, Japan has experienced a series of major earthquakes: the Great Hanshin-Awaji Earthquake (1995), the Great East Japan Earthquake (2011), the Kumamoto Earthquake (2016), and the Noto Peninsula Earthquake (2024). Each caused major damage to water supply infrastructures, particularly water pipes, resulting in large-scale water outages. In addition to these earthquakes, there were main pipeline breaks and outages caused by landslides and other natural disasters that occurred after torrential rains that hit Northern Kyushu in July 2017, heavy rain events in July 2018, and Typhoon Hagibis in 2019.

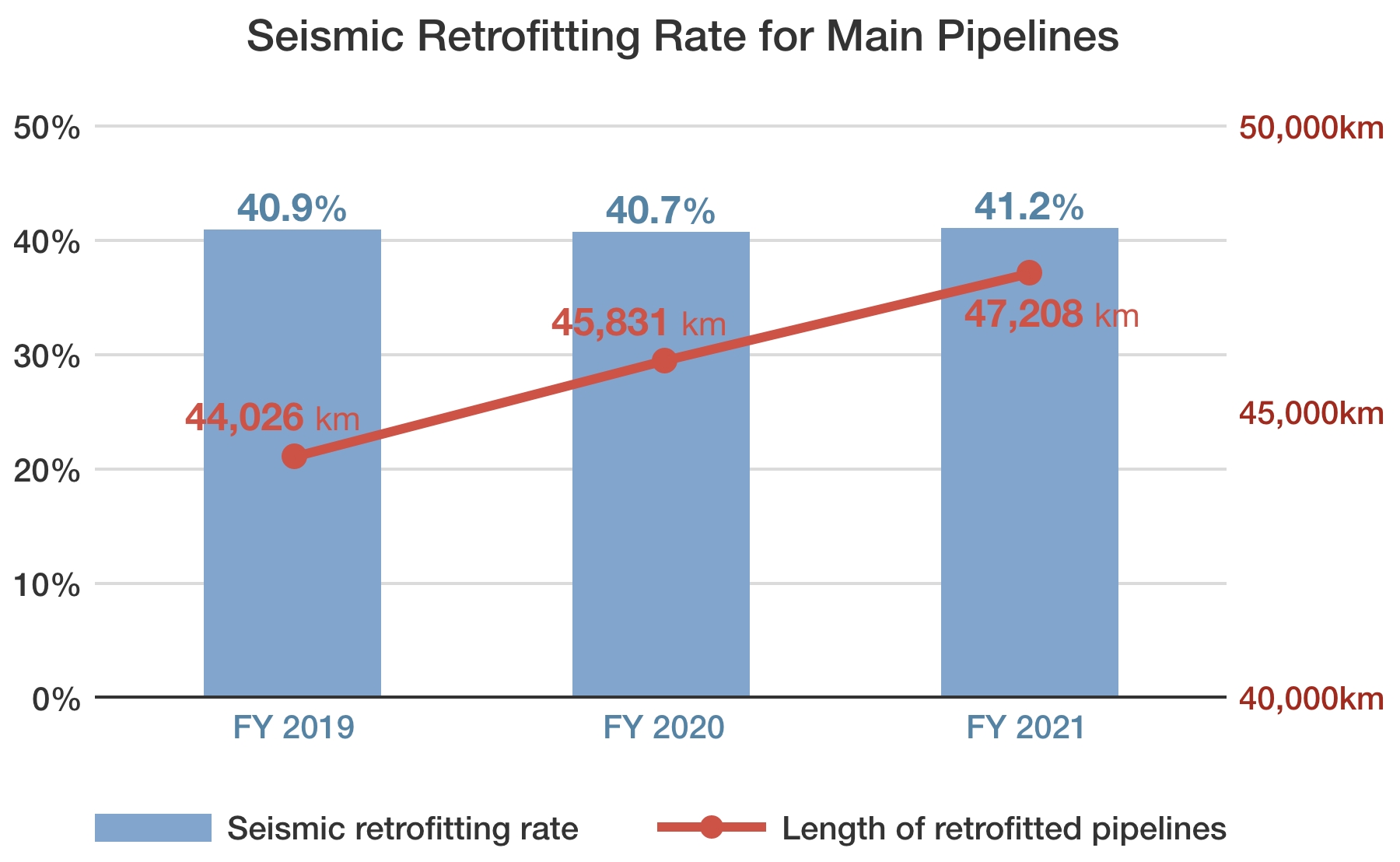

When a water main break occurs, it causes tremendous inconvenience to the people living in the area. However, of Japan’s major water pipelines (main pipelines), only 41.2% are earthquake resistant.

The aging of water infrastructure is another serious problem. About 20% of water pipes in Japan have been in service for over 40 years since they were first laid, which means they have extended their legal service life. Large numbers of engineers are needed to maintain and manage these aging water pipes, but the number of personnel involved in waterworks, including water bureau and waterworks construction company employees, continues to decline. We are now facing a major challenge to ensure that Japan’s safe and reliable water system that was built through the efforts of so many people will continue into the future.

Declaring a Manifesto to Protect Waterworks

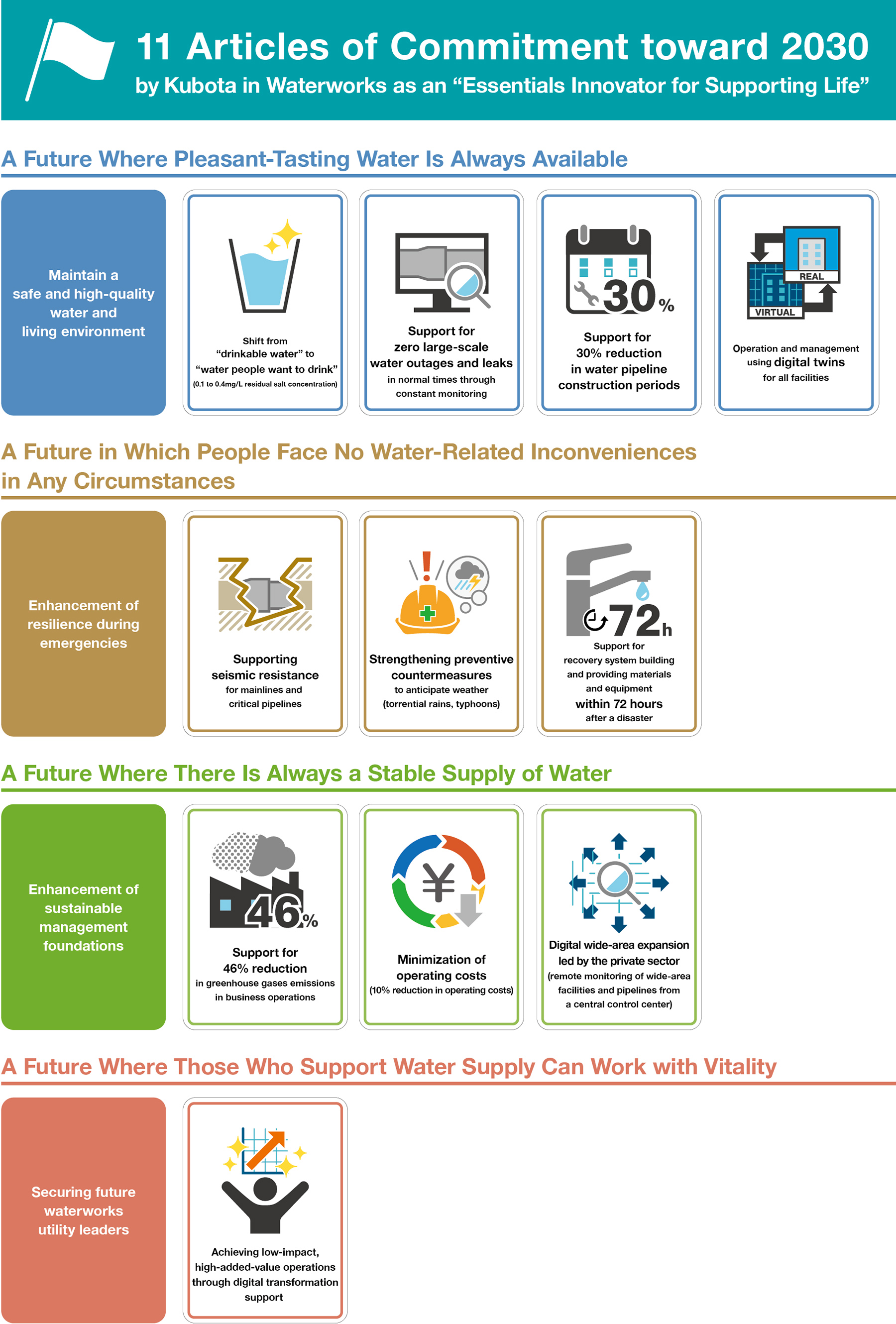

About 130 years ago, Kubota succeeded in the mass production of cast iron water pipes to promote water system proliferation in Japan during the Meiji era (1868-1912), a period in which infectious diseases were spreading rampantly. This contributed to a safer and more reliable water supply. Kubota strives to be an “Essentials Innovator for Supporting Life” through its commitment to a prosperous society and the cycle of nature. Since the company’s founding, it has made solving social problems related to water supply one of its missions. And in its Manifesto listing its initiatives toward the future of water supply, it puts forth Four Futures: “a future where pleasant-tasting water is always available,” “a future in which people face no water-related inconveniences in any circumstances,” “a future where there is always a stable supply of water,” and “a future where those who support water supply can work with motivation.” In addition to these Four Futures, it has declared 11 Articles of Commitment. Kubota aims to achieve these goals by 2030.

Ichikawa explains the reasons Kubota is making such recommendations.

“National and local waterworks bureaus and other water supply utilities are the ones who create policies and operate waterworks. With this in mind, it may seem strange for a private company to be issuing a waterworks manifesto. But solving the pressing issues facing waterworks requires major technological innovations, and leading these innovations is the role of private companies. This is why we at Kubota see significance in issuing this Manifesto.”

A Common Platform for the Future of Waterworks

The 11 Articles of Commitment for the Four Futures for waterworks are required to maintain a safe and high-quality water and living environment, to increase resilience during disasters and other emergencies, to maintain business resilience even in the event of population decrease, and to secure the future leaders of the waterworks industry. For these purposes, the application of the latest ICT will be essential, and AI, IoT, and data will be key in terms of effectively employing limited personnel and budgets.

Kubota has developed and provided an assortment of water-related products over the years. As a highly specialized solutions provider, it is currently working on the KUBOTA Smart Infrastructure System (KSIS), a water and environmental ICT-based solution system designed to improve efficiency and quality in the design, construction, and maintenance of waterworks using the latest information and communications technologies.

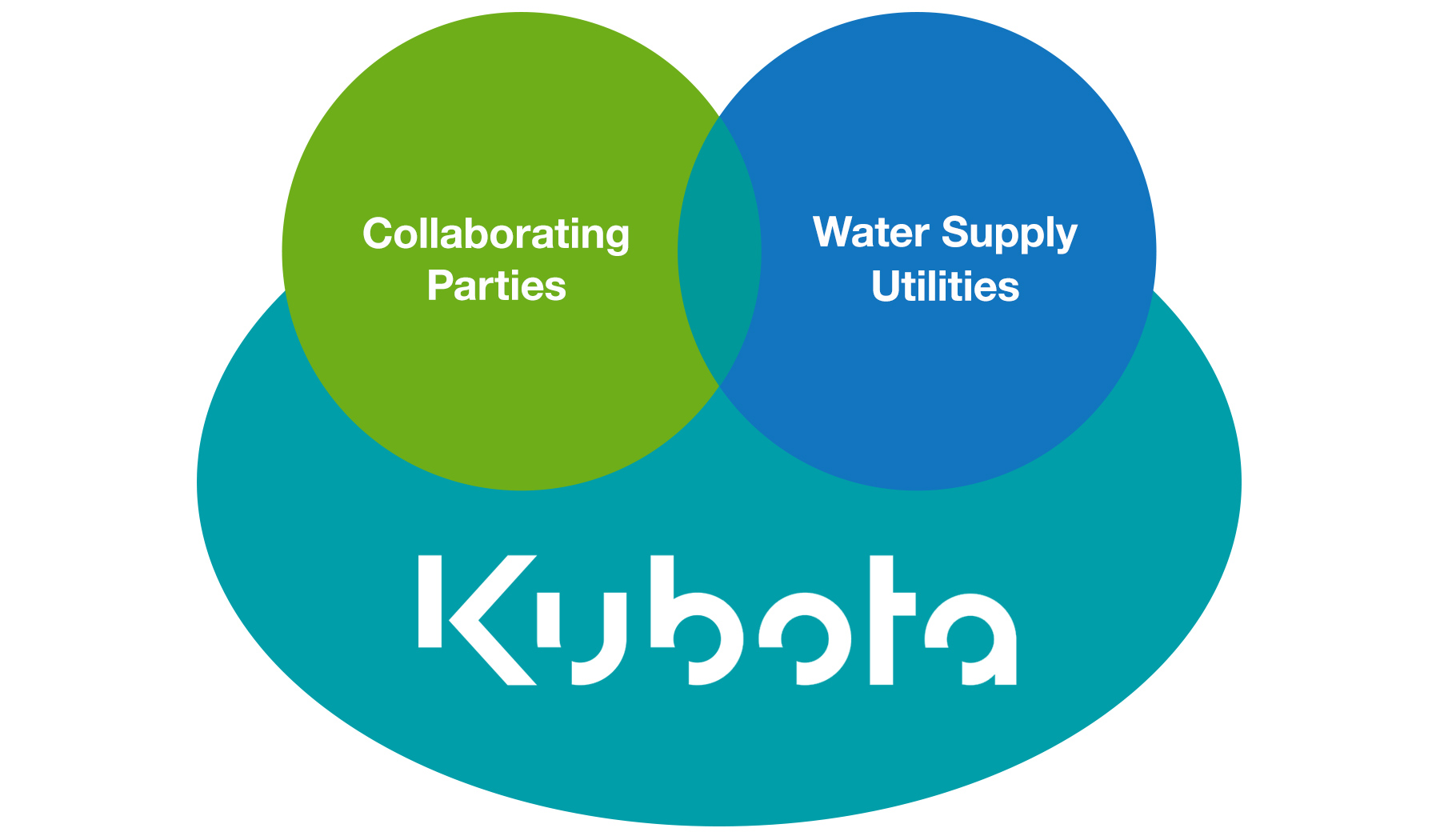

Kubota will provide various technologies and solutions through KSIS to facilitate smoother operations of waterworks, but the efforts to achieve the Manifesto cannot be achieved by Kubota alone. In addition to the main operating entities of water supply utilities, there are many supporting parties involved in waterworks projects, including the engineers and researchers who work to maintain water quality at purification and distribution facilities, as well as companies that provide various technologies and products related to waterworks. If these organizations are not working hand in hand, the future of waterworks cannot be guaranteed.

“Along with developing and providing individual solutions, Kubota is working on the construction of a platform that aims to improve the level, efficiency, and quality of overall operations by storing all data related to the processes of waterworks infrastructure, including maintenance, upgrade planning, design and construction, in the cloud and sharing it among all operations,” says Ichikawa. “We want to use this platform as we aim to achieve the 11 Articles of Commitment along with stakeholders involved in waterworks businesses.”

Concrete Initiatives toward Achieving the Manifesto

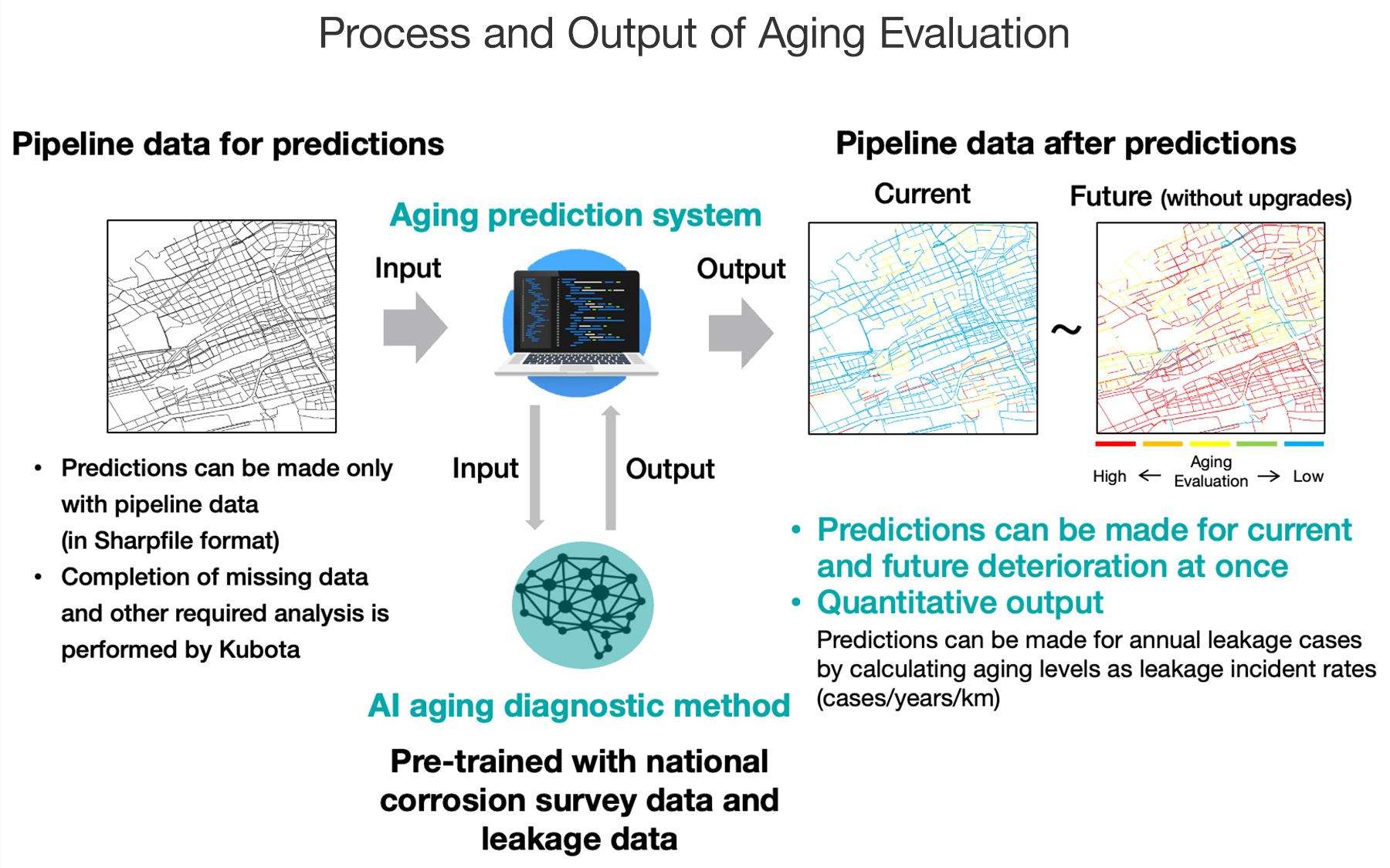

For example, achieving the objectives in the articles of “supporting seismic resistance” and “strengthening preventive countermeasures” requires systemic upgrades of aging pipes to earthquake-resistant pipes. The degree to which pipes have aged is currently estimated mainly by using the number of years since the pipes were laid. However, pipe condition cannot be entirely determined just by their years of service; it must be determined comprehensively using a number of criteria related to their burial conditions, such as ground quality, pipe type, and how the roads are being used. If we have large amounts of data related to these factors, this data can be fed to AI to create predictive models for aging diagnostics, evaluate pipe condition with greater precision, and support formulation of upgrade plans based on an appropriate order of priority.

Furthermore, enabling the commitment of “support for zero large-scale outages or leaks” requires status monitoring of water pipelines. However, the conditions of pipes buried underground cannot be directly observed from above ground. Leakages are often determined by multiple surveyors using listening rods and other testing equipment above the waterways. If personnel can use sensing devices such as valves equipped with IoT sensors to remotely monitor data on water pressure and flow within pipelines, they will be able to detect leaks and other abnormalities in pipes without having to go directly to the sites.

These kinds of data that are collected and stored through maintenance and management of water pipes can be applied during the design and construction processes as well. A method called design-build (DB) in which design and construction of water pipelines are ordered in a single contract has become more common in recent years, and with a system through which AI is used to support design, waterworks companies in various regions would be able to place orders for pipeline construction using the DB method.

One advantage when waterworks companies can handle processes from design to construction is the ability to adapt more smoothly to design changes in response to local conditions and the resulting adjustments in construction costs. Systems can also be used in which work results data is collected and imported on-site using smartphones and IoT devices, and this data can be used to automatically generate work-related documents. These capabilities would dramatically reduce the workload of project supervisors, allowing them to devote more of their time to actual on-site work. This can enable “support for 30% reduction in water pipeline construction periods,” one of the 11 Articles of Commitment.

Efforts to Utilize Cutting-Edge ICT by Japan’s Water Supply Utilities

Fukuoka City in Fukuoka Prefecture, which lacks abundant water resources due to its geographic conditions, is undertaking regular leakage survey and water pipeline upgrades as it aims to maintain its rate of leakages, the lowest in the world. However, one issue that it has faced was the effort and time required to accumulate the survey data for excavating roadways. To address this, the city’s Waterworks Bureau launched “water pipe aging prediction using AI” in a joint research project with a private firm. The AI aging evaluation method jointly developed by Kubota and the University of Tokyo confirmed that as a result, pipe aging could be predicted with higher accuracy based on large amounts of core data without having to excavate the roads.

“The AI aging evaluation method was developed through joint research with the University of Tokyo based on corrosion survey and burial environment data that Kubota has collected over the years for approximately 6,000 pipes throughout Japan. It provides dramatic improvements in accuracy over conventional aging prediction methods, and if the top 20% of aged pipes are upgraded based on these results, incidents of leakage can be halved compared to conventional methods.”

Moreover, Kobe City in Hyogo Prefecture, which in 1900 became the seventh city in Japan to begin supplying water through modern waterworks, is maintaining and managing water pipelines that extend for a total length of over 4,880 kilometers. As funds collected for water services decline due to the falling population, upgrading the aging pipelines has become a huge burden, and how to achieve this efficiently is a challenge.

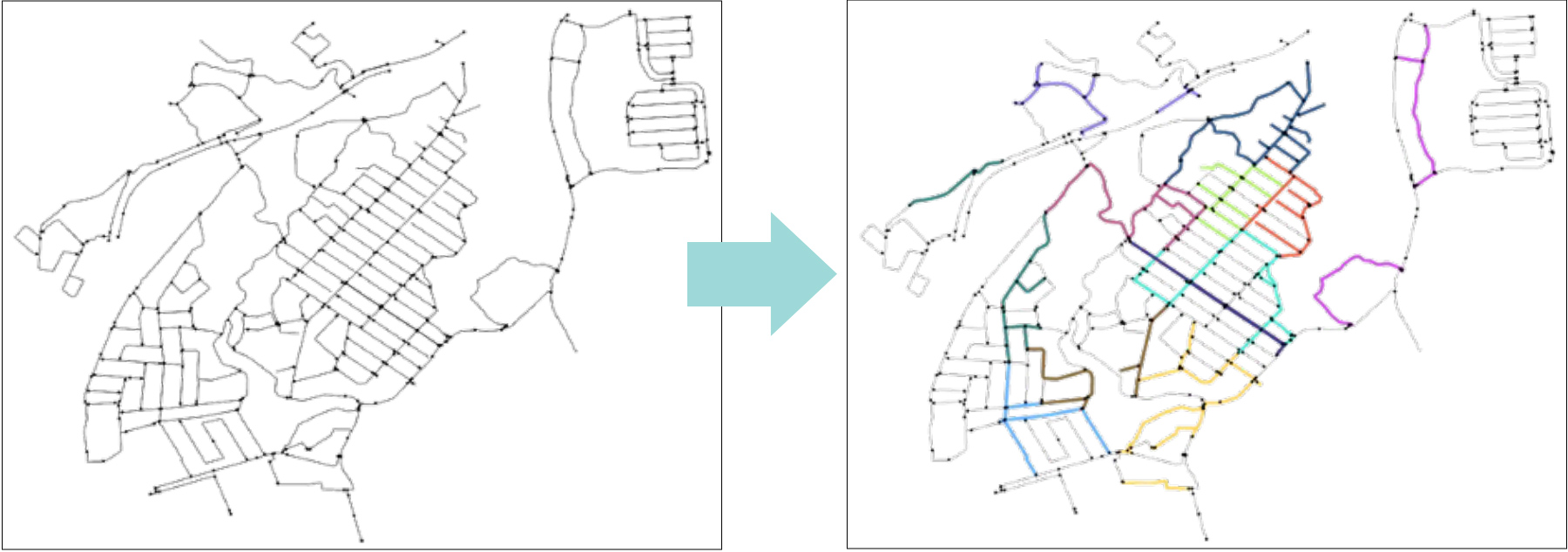

To address this, Kubota has developed Appropriate Construction Order Grouping, a technology that automatically divides or groups the construction sections of intricate water pipeline networks for the development of pipeline upgrade plans into arbitrary sizes based on criteria including construction costs and pipe length. This AI-based system was developed through joint research with the Kobe Waterworks Bureau.

“By applying this technology, the burden of setting up construction sections by engineers can be drastically reduced at water supply utilities, which are facing personnel shortages. It used to take about two weeks for one engineer to do grouping for a 20-kilometer pipeline extension grouping, but we have verified that this technology enables us to do about 600 kilometers of pipeline extension grouping in about an hour.”

The example from Kobe aims to achieve the article of “achieving low-impact, high-added-value operations through digital transformation support.”

One more example that connects to the article of “support for 30% reduction in water pipeline construction periods” is from the East Gunma Water Supply Authority, which provides waterworks services in the eastern part of Gunma Prefecture. It has adopted the DB method utilizing Kubota’s total water pipeline solutions in an effort to maintain design and construction quality, use rational design, and increase project speed. Plus, the Hachinohe Regional Water Supply Authority, which oversees waterworks operations in an area focused on Hachinohe City in Aomori Prefecture, is promoting the use of a system that makes water pipeline construction management more efficient by linking smartphones and data. These initiatives with Kubota aim to provide a better future for waterworks in various regions.

“We want to keep pursuing our efforts with these water supply utilities while we connect individual solutions on a shared platform that we can use to provide total solutions.”

Solving Global Water Problem with Japan-based Initiatives

For about 130 years, since becoming the first company in Japan to succeed in the development, domestic production, and mass production of cast iron water pipes, Kubota has devoted itself to efforts to supply safe water to people, accumulating and analyzing technologies, expertise, and data along the way.

“I can say with confidence that only Kubota can provide the platform that serves as a common foundation for collaboration among various entities and companies involved in waterworks from the standpoint of a private company.”

Ichikawa adds that creating a new standard for waterworks through these efforts will have huge significance for the global water industry.

“In terms of water-related initiatives and technologies, Japan is a global leader. The risks that Japan faces will eventually come to every country and territory that uses water supply. For us to work together to overcome these challenges in Japan means that we can save the world from water-related dangers.”