The United Nations has reported that more than 60% of the world’s population will live in cities by 2030, with urban populations increasing by 5.5 million each month, especially in developing countries. In response to the problems caused by the sudden increase in urban populations, Goal 11 of the SDGs is to “Make cities inclusive, safe, resilient and sustainable,” and this requires improvements in social infrastructures and enhancements in public services. In this edition of KUBOTA STORIES, we spotlight Kubota’s construction machinery business and how it contributes to improvements in urban environments.

Kubota Continues to Tackle Social Issues Resulting from Urbanization

How is Kubota contributing to the refurbishment and redevelopment of urban infrastructure in developed nations and the rapid progress of urban development in emerging nations? We asked Katsuhiko Yukawa, General Manager of Kubota’s Construction Machinery Division.

“We at Kubota consider the social issues facing cities to be an opportunity to show Kubota’s reason for existing.”

“About 130 years ago, as Japan was in the midst of modernization, Kubota began working to address the issues that cities were having with water infrastructure, which was required to stop the spread of cholera and other infectious diseases. The company began developing cast iron water pipes, and it succeeded in becoming the first company in Japan to successfully mass-produce these pipes. The company has grown since then by providing products and solutions that contribute to addressing not only urban problems but also a wide range of social issues. The Construction Machinery Division that I manage has specialized in the domain known as compact construction machinery including the mini excavator, which has led the world in sales* since 2002, as well as compact track loaders (CTL) and skid steer loaders (SSL), which are highly regarded in North America. The division has expanded by responding to diversifying needs for urban construction projects. In recent years, we have been working on ways to balance urban development and redevelopment with environmental conservation, and to address personnel shortages in construction work.”

- * Less than 6 tons. From Off-Highway Research 2023

The construction industry plays a vital role in promoting urbanization, but staff shortages are an issue worldwide, and this problem has become increasingly serious in Japan.

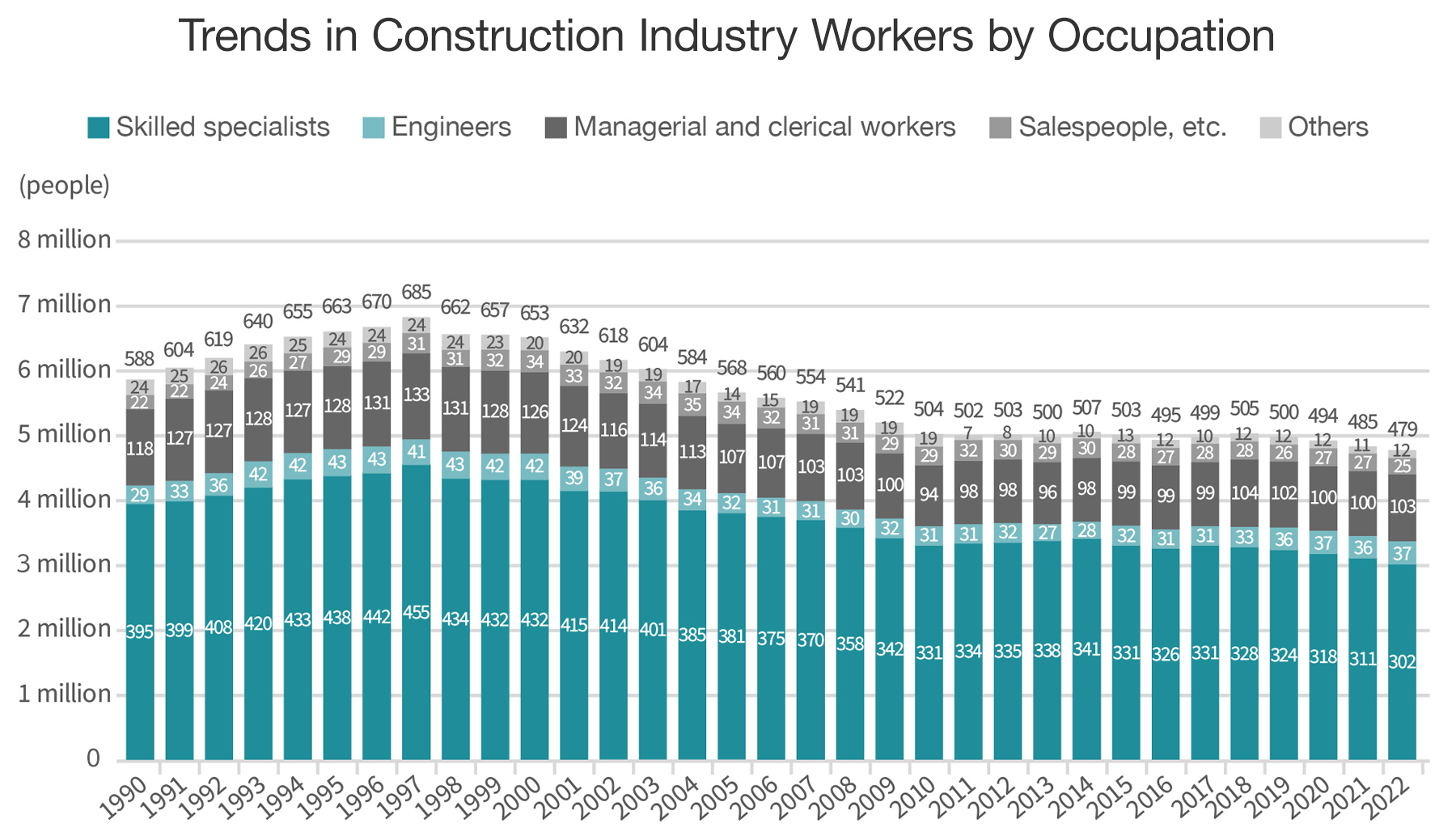

Labor shortages are becoming a social problem throughout the world, particularly in developed countries that face falling birth rates, aging populations, and declining numbers of working-age people. This is an especially serious problem in Japan, and in the construction industry, among various occupations, the number of skilled specialists who work directly on projects has continued to fall from its 1997 peak, with a decrease of 1.53 million by 2022.

“In addition to the shortage of workers, the decline in skilled operators at construction sites is becoming a problem. This trend is more apparent in the so-called developed countries. Jobs that could be completed quickly by a highly experienced and skilled operator are taking a long time, and construction projects are taking longer due to the decline in workers. There is concern that this will make it more difficult to quickly respond when there is highly urgent construction work such as disaster recovery. That is why Kubota is moving forward with a digital transformation aimed at improving work efficiency for operators.”

“With heavy-duty construction machinery, Kubota has already taken initiatives to make work more efficient even when skilled operators are not present by importing maps and other data into the machinery in advance. In urban construction projects where compact construction machinery plays a role, Kubota is applying ICT and the latest technologies to enable more efficient work and safer construction.”

“Meanwhile, in developing countries where urbanization is proceeding rapidly, much of the construction work is still done by hand. For this reason, improving urban environments takes longer, and working conditions are harsh. We believe the first step is a shift toward mechanization. Kubota wants to contribute to improving urban environments by providing our simple and easy to operate machines that have been refined on construction sites worldwide at the lowest prices possible.”

The Operator-Friendly Construction Machinery that Workplaces Need

Throughout its history, Kubota has expanded its business worldwide by responding to customer needs, enhancing its product lineup, taking a thorough approach to operability, and making improvements in functionality and quality. CTLs, which are the key to the company’s growth in the North American market, are said to have earned an excellent reputation despite their late entry to the market. We asked Yukawa why this was the case.

“The mini excavator does an excellent job with excavation work, but it moves slowly under its own power, so when transporting excavated soil and materials to construction sites, it is more efficient and common to use a machine with advantages in material handling. With material handling machinery in the U.S. in the 2000s, most of the equipment was SSLs from other manufacturers, but for the operators it was a taxing environment. Think about the low height and narrow field of view of SSLs. And they are built with arms on either side of the operator’s seat, which limits entry and exit to the front. This is extremely dangerous because, for example, the swinging door may not open in the event of a fall. On top of that, what surprised me most was its ride comfort. When you drive while lifting a heavy object, the wheel tires make the machine sway violently. When I drove an SSL myself, I realized how rigorous it was.”

“When I was about to drive one for myself,” recalls Yukawa, “I was warned by others around me, ‘You’ll need motion sickness medicine.’ I got into the SSL thinking there’s no way I would get motion sickness. But in less than 30 minutes, I started to feel ill.” This is when Kubota turned its attention to the CTL.

“A CTL has crawler belt wheels. These glide smoothly and generate less noise and vibration. Kubota was a newcomer to the CTL, but it developed the machine from an operator’s perspective, with more space inside the operator’s seat and improved operability – that is, an operator-friendly way, incorporating Kubota’s unique strengths. Kubota’s CTL is designed with the idea that improving operability will improve work efficiency, making it so that the same job can be done in a less tiring and faster way.”

Yukawa says the key to developing this machine was “problem-solving from the customer’s perspective.” That means the development staff visited projects on-site and checked the products with their own eyes to accurately assess the problems that were happening. However, he stresses that product development alone is not enough.

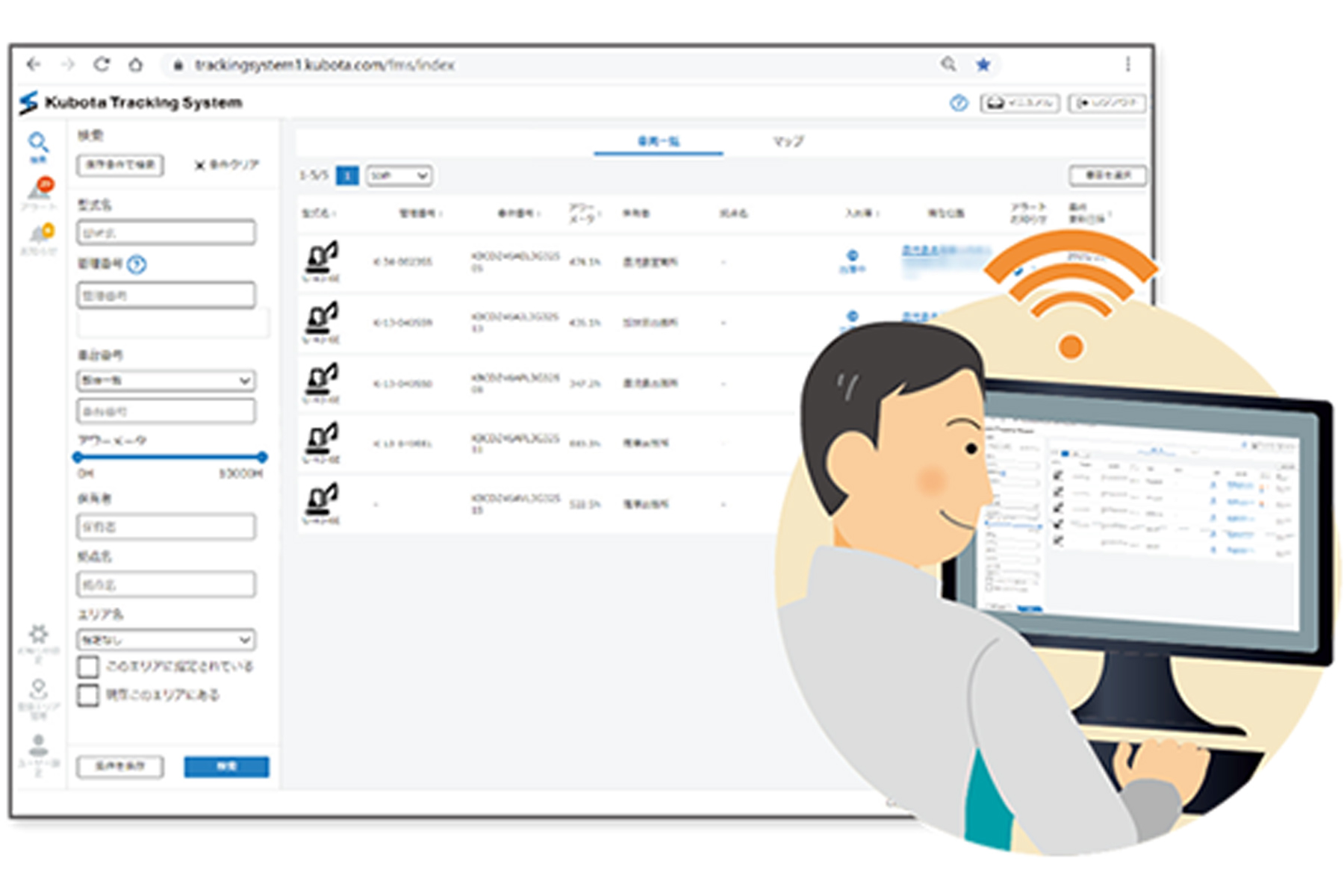

“With construction machinery, it’s important to consider the product and service as the two pillars. Construction machinery requires more maintenance than automobiles, so even the best products won’t sell if service is not up to par. Our service system can immediately respond to problems, and this is one of Kubota’s biggest selling points. Currently, to enhance this service, we are adding telematics (remote data exchange system) and applying the information we get from customers’ equipment to service that responds to problems and development of products for future seasons.”

Further Advancing Technologies and Contributing to Carbon Neutrality

Kubota has earned an excellent reputation in North America for its material handling machinery such as the CTL and SSL. However, these machines are only capable of moving when they are used independently. By replacing the part at the end of the arm called an attachment, one machine can become more versatile for a variety of tasks, including excavation, logging, hauling, and landscaping, leading to solutions to personnel shortage problems. Yukawa says this is an area where Kubota will be able to demonstrate its advantages.

“In North America, Kubota has a strategic alliance with Great Plains Manufacturing (GPM), an implement manufacturer that has been brought into the Kubota Group. Kubota will produce and manufacture the main units for the CTL and SSL, while GPM will develop and manufacture attachments, with the goal of offering both products together in the U.S. market. In addition, we will develop and manufacture ‘smart attachments’ that enable work to be performed smoothly even without skilled operators.”

“Usually, the material handling machine body and attachment are connected through the hydraulic and electrical systems, and operators manually make different settings for each attachment. With smart attachments, the attachment sends the necessary information to the main body, so settings are done automatically. This means even less-experienced operators can configure settings easily, improving operational efficiency.”

Yukawa also points out the need to help reduce environmental impact while improving urban environments in the future. We asked about the efforts toward its Kubota’s Environmental Vision targeting 2050.

“Kubota is aiming to contribute to the achievement of a carbon-neutral and resilient society in the fields of food, water, and the environment while striving for zero environmental burden. The general way of thinking is that reducing environmental impact means battery-based electrification, but there are some areas of industrial machinery that cannot run on the electricity from batteries alone, so we will be taking an all-inclusive approach toward achieving zero environmental impact. The first step will be to further enhance our energy-saving and exhaust gas reduction efforts in diesel engines. Then, in addition to the electrification through batteries we have already achieved, we will push forward with electrification through hydrogen fuel cells and development of engines powered by hydrogen, biofuels, and synthetic fuels. We will be making efforts toward carbon neutrality in all aspects with a view toward technological breakthroughs in the near future.”

Changes and Constants Heading Toward the Future

Although Kubota products are now at work in construction sites throughout the world, Yukawa knows that the road to this point has not always been smooth sailing. He says the company needs to focus on its start-up spirit.

“When I joined the company, the Construction Machinery Division had much less business and less influence on society than it does now. That is why we had no choice but to grow as a business, and this meant incorporating customer feedback into our products and taking on lots of new challenges. We were able to accomplish our goals by taking on the consciousness of a start-up. Even now, when we launch new products to the market, we haven’t lost the desire to ask, ‘Is this product really for the benefit of the customer?’ There are lots of conflicting elements in a single product, but determining what to prioritize in development requires us to look at actual products at customers’ work sites and listen to what customers have to say. Keeping this start-up spirit and continuing to work while thinking of what products and services can respond to customer issues will be a Kubota advantage, and I want to keep prioritizing that.”

Yukawa wraps up by saying that to keep providing solutions to social issues that change with the times is the expected role of Kubota as an “Essentials Innovator for Supporting Life.”

“We get recognition from our customers by solving problems, and we use the profits given to us by our customers as funds for our next solutions, all to contribute to the realization of a sustainable society. Kubota is involved in the broad-ranging business domains of food, water, and the environment, and there are many things that we can do in terms of business projects. This means we have a great deal of responsibility, but because Kubota’s mission is to solve the social problems that deeply affect people's lives, we will make sure to fulfill the role expected of us.”

Half a century has passed since the launch of the mini excavator. The efforts of the Kubota’s construction machinery business, which started from the drive to improve Japan’s infrastructure, will continue to evolve in order to solve urban development problems throughout the world.